3D Printing Services in New York City

For Prototypes, Production Parts, & Complex Geometries

We help artists, brands, studios, engineers, and architects turn digital designs into physical objects—accurately, efficiently, and at production quality.

Whether you’re prototyping, validating form and fit, or producing end-use parts, we pair advanced printing technologies with expert material and process selection.

Start A Project

3D Printing Technologies We Offer

FDM 3D printing (Fused Deposition Modeling), also known as FFF (Fused Filament Fabrication), is a widely used additive manufacturing process that creates parts by extruding heated thermoplastic filament layer by layer through a precision nozzle. This technology is valued for its affordability, material versatility, and ability to produce durable, functional parts.

At Kemperle Industries, FDM is used for functional prototyping, low-volume production, and end-use components where strength, reliability, and material performance are critical.

FDM 3D Printing Materials

We offer a range of thermoplastics selected to meet structural, thermal, and environmental requirements:

-

-

PLA (Polylactic Acid)

The most widely used and commonly available FDM material. PLA is a plant-based thermoplastic well suited for concept models, early-stage prototypes, and visual parts where ease of printing and dimensional accuracy are priorities. -

ABS (Acrylonitrile Butadiene Styrene)

A tough, impact-resistant plastic used in many consumer and industrial products—including LEGO® bricks. ABS is ideal for functional prototypes, housings, and automotive components that require durability. -

TPU (Thermoplastic Polyurethane)

A flexible, elastomeric material ideal for parts requiring elasticity, impact absorption, or grip, such as seals and protective components. -

PETG (Polyethylene Terephthalate Glycol-Modified)

A strong, chemically resistant material well suited for outdoor applications and parts exposed to the elements. PETG performs well in environments involving moisture, UV exposure, or temperature variation. -

ULTEM® (Polyetherimide / PEI)

A high-performance engineering thermoplastic offering excellent heat resistance, flame retardancy, and strength. Commonly used in aerospace, transportation, and industrial applications. - PEEK (Polyether Ether Ketone)

An advanced thermoplastic known for exceptional mechanical strength, chemical resistance, and high-temperature performance, suitable for demanding industrial and medical applications. - PEKK (Polyetherketoneketone)

Similar to PEEK, with enhanced processing characteristics and excellent thermal and mechanical stability for aerospace and high-performance environments. - PPSU (Polyphenylsulfone)

A high-strength, chemically resistant polymer often used in medical, aerospace, and food-contact applications due to its toughness and stability. - PC (Polycarbonate)

A strong, impact-resistant material with good heat resistance, commonly used for enclosures, housings, and structural components. - Carbon Fiber– or Glass Fiber–Filled Nylon (PA12-CF / PA12-GF)

Reinforced nylons that provide increased stiffness, dimensional stability, and strength-to-weight performance, ideal for tooling, fixtures, and structural parts.

-

FDM 3D Printing Applications

FDM is well suited for applications that require durability, rapid iteration, and cost-effective production:

-

Aerospace

Lightweight components, enclosures, housings, and antenna covers -

Automotive

Assembly tools, jigs, fixtures, and functional prototype parts -

Consumer Electronics

Custom enclosures, housings, and structural components -

Medical

Custom prosthetics, anatomical models, and form-fit validation parts

When to Choose FDM 3D Printing

FDM is ideal when projects require durable thermoplastic parts, cost-effective low-volume production, or functional testing prior to full-scale manufacturing.

SLA 3D printing, or Stereolithography, is a high-resolution additive manufacturing process that uses a focused light source to cure liquid photopolymer resin layer by layer. SLA is known for its exceptional surface finish, fine detail, and tight tolerances, making it ideal for visually critical and precision-driven parts.

There are three primary SLA light-source technologies—MSLA, Laser, and DLP—each offering different advantages depending on speed, resolution, and part size.

At Kemperle Industries, we select the appropriate SLA method based on part geometry, tolerance requirements, surface finish expectations, and production timelines.

SLA Light Source Technologies

-

MSLA (Masked Stereolithography)

Uses an LCD screen as a mask over a UV light source to cure entire layers at once. MSLA offers fast print times and high XY resolution, making it well suited for detailed prototypes and small to medium-sized parts. -

Laser

Uses a focused laser to trace and cure resin point by point. This method provides excellent accuracy and surface consistency, particularly for parts requiring precise edge definition and smooth curves. -

DLP (Digital Light Processing)

Uses a digital projector to cure an entire layer simultaneously. DLP combines speed and accuracy, producing uniform layers with sharp detail, especially for smaller, highly detailed components.

SLA 3D Printing Materials

We offer a range of professional-grade resins engineered for visual fidelity, strength, and functional performance:

-

Standard Resins

Ideal for concept models, presentation pieces, and visual prototypes requiring smooth surfaces and fine detail. -

Tough & Engineering Resins

Designed to mimic ABS-like performance, offering improved durability and impact resistance for functional testing. -

High-Temperature Resins

Engineered for applications requiring elevated thermal resistance, such as tooling inserts and fixtures. -

Flexible & Elastomeric Resins

Suitable for parts requiring limited flexibility, snap-fit features, or soft-touch characteristics.

SLA 3D Printing Applications

SLA excels in applications where surface finish, precision, and detail resolution are critical:

-

Product Design & Engineering

High-fidelity prototypes, form-fit validation, and design verification models -

Manufacturing & Tooling

Master patterns for molding and casting, jigs, and fixtures -

Architecture & Design

Detailed scale models and presentation components -

Medical & Healthcare

Anatomical models, surgical planning aids, and device prototypes

When to Choose SLA 3D Printing

SLA is the preferred choice when projects demand exceptional surface quality, fine feature detail, and tight dimensional control, especially for presentation models or tooling masters.

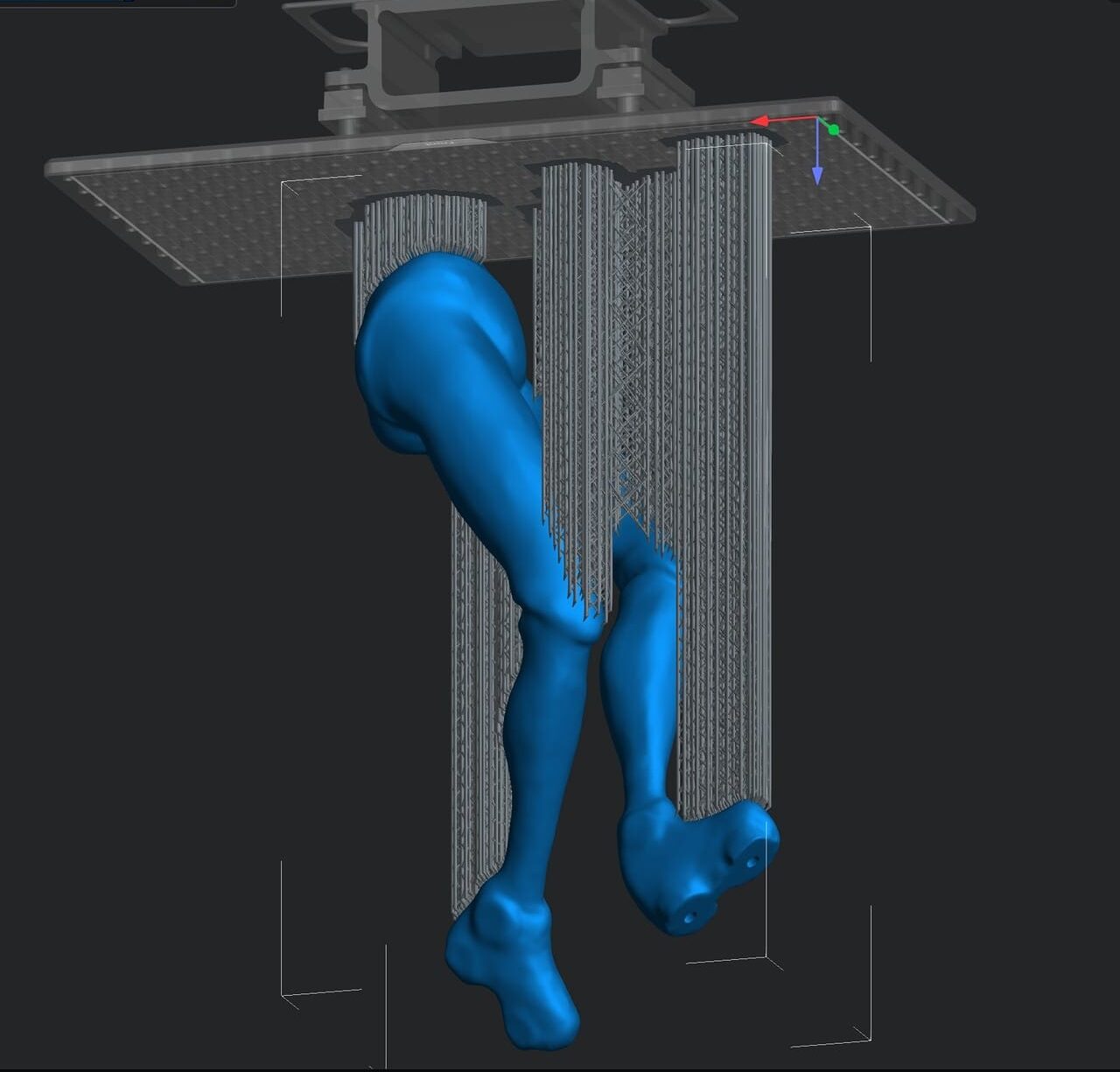

SLS 3D printing, or Selective Laser Sintering, is a powder-bed additive manufacturing process that uses a laser to fuse thermoplastic powder into solid parts layer by layer. SLS is widely used for durable, functional components and production-ready plastic parts that require strength, complexity, and consistent mechanical performance.

Instead of relying on traditional support structures—such as those required in FDM or SLA—SLS uses the surrounding, unfused powder as its support structure during printing. Each part is fully encased within unused powder throughout the build.

Once printing is complete, the build is allowed to cool, after which excess powder is brushed and blown off, freeing the finished 3D printed part. This process enables complex geometries, internal channels, and nested parts without the need for removable supports.

At Kemperle Industries, SLS is used for functional prototypes, end-use parts, and low-volume production where durability and design freedom are essential.

SLS 3D Printing Materials

SLS materials are chosen for their mechanical strength, thermal stability, and wear resistance:

-

Nylon (PA 11 / PA 12)

Strong, lightweight thermoplastics with excellent chemical resistance and long-term durability, ideal for functional parts. -

Glass- or Mineral-Filled Nylons

Reinforced materials offering increased stiffness, dimensional stability, and thermal resistance. -

Flexible Nylon Blends

Suitable for snap-fit parts, living hinges, and impact-resistant components.

SLS 3D Printing Applications

SLS is widely used for parts that must perform under real-world conditions:

-

Automotive & Transportation

Functional housings, ducts, brackets, and snap-fit components -

Industrial & Manufacturing

End-use parts, assemblies, and production-ready components -

Consumer Products

Durable enclosures, wear-resistant parts, and complex assemblies -

Medical Devices

Orthotics, prosthetic components, and functional medical housings

When to Choose SLS 3D Printing

SLS is ideal when projects require strong, production-grade thermoplastic parts, complex geometries without supports, and consistent mechanical performance across all axes.

DLSM 3D printing—often referred to as Direct Laser Metal Sintering (DMLS) or Selective Laser Melting (SLM)—is a metal additive manufacturing process that uses a high-powered laser to fuse fine metal powder into dense, high-strength parts layer by layer. DLSM is used when mechanical performance, thermal resistance, and structural integrity are critical.

At Kemperle Industries, DLSM is applied to functional metal components, complex internal geometries, and low-volume production parts where traditional machining would be impractical or cost-prohibitive.

DLSM 3D Printing Materials

We work with industry-standard metal alloys selected for strength, heat resistance, and durability:

-

Stainless Steel

Corrosion-resistant and mechanically robust, suitable for tooling, housings, and structural components. -

Aluminum Alloys

Lightweight with good strength-to-weight ratio, commonly used in aerospace and transportation applications. -

Tool Steels

High hardness and wear resistance for tooling, molds, and industrial components. -

Specialty Alloys (project-dependent)

Materials selected based on thermal, mechanical, or environmental performance requirements.

DLSM 3D Printing Applications

DLSM is widely used for mission-critical and high-performance parts:

-

Aerospace & Defense

Lightweight structural components, brackets, and internal channels -

Automotive & Motorsports

High-strength components, performance parts, and custom fixtures -

Industrial Manufacturing

Tooling inserts, heat exchangers, and production-grade metal parts -

Engineering & R&D

Complex geometries not achievable through traditional machining

When to Choose DLSM 3D Printing

Choose DLSM when projects require fully dense metal parts, high mechanical performance, and complex internal geometries that cannot be produced through conventional manufacturing.

PolyJet 3D printing is a high-resolution additive manufacturing process that jets and cures liquid photopolymer droplets simultaneously, allowing for multi-material and full-color printing in a single build. PolyJet excels at visual realism, fine detail, and material simulation.

At Kemperle Industries, PolyJet is used for presentation models, ergonomic prototypes, and design validation parts where appearance, texture, and material behavior are essential.

PolyJet 3D Printing Materials

PolyJet enables simultaneous use of multiple photopolymers within a single part:

-

Rigid Photopolymers

Smooth, high-detail materials ideal for visual prototypes and housings. -

Flexible & Rubber-Like Materials

Elastomeric resins used to simulate soft-touch components, grips, and seals. -

Digital Materials

Composite materials created by blending rigid and flexible resins to simulate specific material properties. -

Full-Color Materials

Enable photorealistic color gradients, labels, and textures directly in the print.

PolyJet 3D Printing Applications

PolyJet is ideal for projects requiring visual accuracy and material simulation:

-

Product Design & UX

Ergonomic studies, form validation, and presentation prototypes -

Consumer Electronics

Multi-material housings, buttons, and interfaces -

Medical & Healthcare

Anatomical models, surgical planning tools, and device visualization -

Marketing & Sales

Photorealistic prototypes and display models

When to Choose PolyJet 3D Printing

Choose PolyJet when projects demand high visual fidelity, multi-material behavior, or full-color realism, rather than structural or long-term mechanical performance.

MJF 3D printing, or Multi Jet Fusion, is a powder-bed additive manufacturing process that uses inkjet agents and thermal energy to fuse thermoplastic powder into strong, highly detailed parts. MJF produces parts with excellent mechanical properties and faster build times compared to traditional powder-based systems.

At Kemperle Industries, MJF is used for functional prototypes, end-use components, and low- to mid-volume production where strength, repeatability, and surface consistency are required.

MJF 3D Printing Materials

MJF materials are selected for durability, consistency, and production-readiness:

-

Nylon PA 12

Strong, wear-resistant, and chemically stable, ideal for end-use parts. -

Glass-Filled Nylon

Increased stiffness and dimensional stability for structural components. -

Flame-Retardant & Specialty Nylons (project-dependent)

Used for regulated or performance-critical environments.

MJF 3D Printing Applications

MJF is widely adopted for production-focused applications:

-

Automotive & Transportation

Functional housings, ducts, clips, and brackets -

Industrial Manufacturing

End-use components, fixtures, and repeatable production parts -

Consumer Products

Durable enclosures and snap-fit assemblies -

Medical Devices

Functional housings and device components

When to Choose MJF 3D Printing

Choose MJF when you need strong, production-ready thermoplastic parts, consistent mechanical properties, and efficient low- to mid-volume manufacturing.

Ornamental Plaster Master Pattern

3D printing a master pattern of an ornamental plaster element for a residential interior.

Replica of the Academy Awards Oscar

3D printing a replica of the Academy Awards Oscar for molding and resin casting.

3D Printed Plaster Column Base

SLA 3D printing a master pattern for an ornamental plaster mould.

Frequently Asked Questions

Which 3D printing technology is best for functional parts?

There is no single best 3D printing method for functional parts. FDM, SLS, and SLA can all produce durable components when matched with the right materials and design intent.

→ Read our full guide to choosing the right 3D printing technology for functional parts.

Can you help choose the right 3D printing technology for my project?

Yes. Kemperle Industries evaluates material performance, tolerances, surface requirements, and end-use conditions to recommend the best technology for each project.

Which 3D Printing Technology is best for my project?

Choosing the Right 3D Printing Technology: A Complete Comparison Guide

Which 3D printing technology is best for functional parts?

How does scan-to-print work?

Scan to Print: A technical guide to turning physical objects into production-ready 3D printed parts