Bold Designs, Expertly Built

We partner with brands, agencies, and experiential design teams to transform bold ideas into expertly crafted physical forms. From high-impact displays to sculptural installations, we help you deliver projects that stand out.

What We Can Build

Custom Retail Displays

- Distinctive in-store fixtures

- Sculptural window pieces

- Branded elements engineered for precision and visual impact

Experiential Fabrication

- Interactive exhibit elements

- Customized brand pieces

- Unique 3D signage

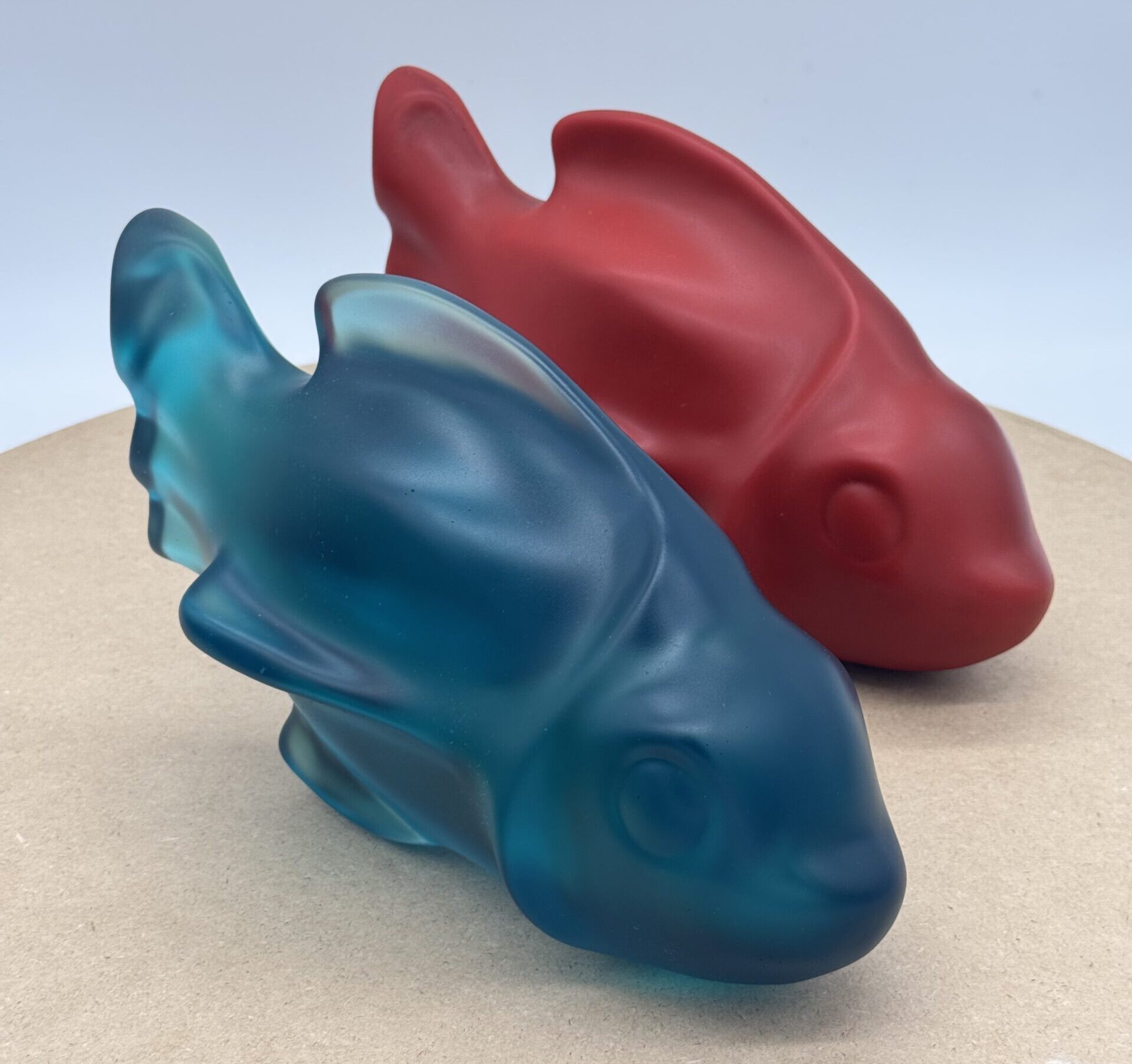

Brand Activation Builds

- Prototypes

- Scaled replicas

- One-of-a-kind sculptural pieces built to showcase products

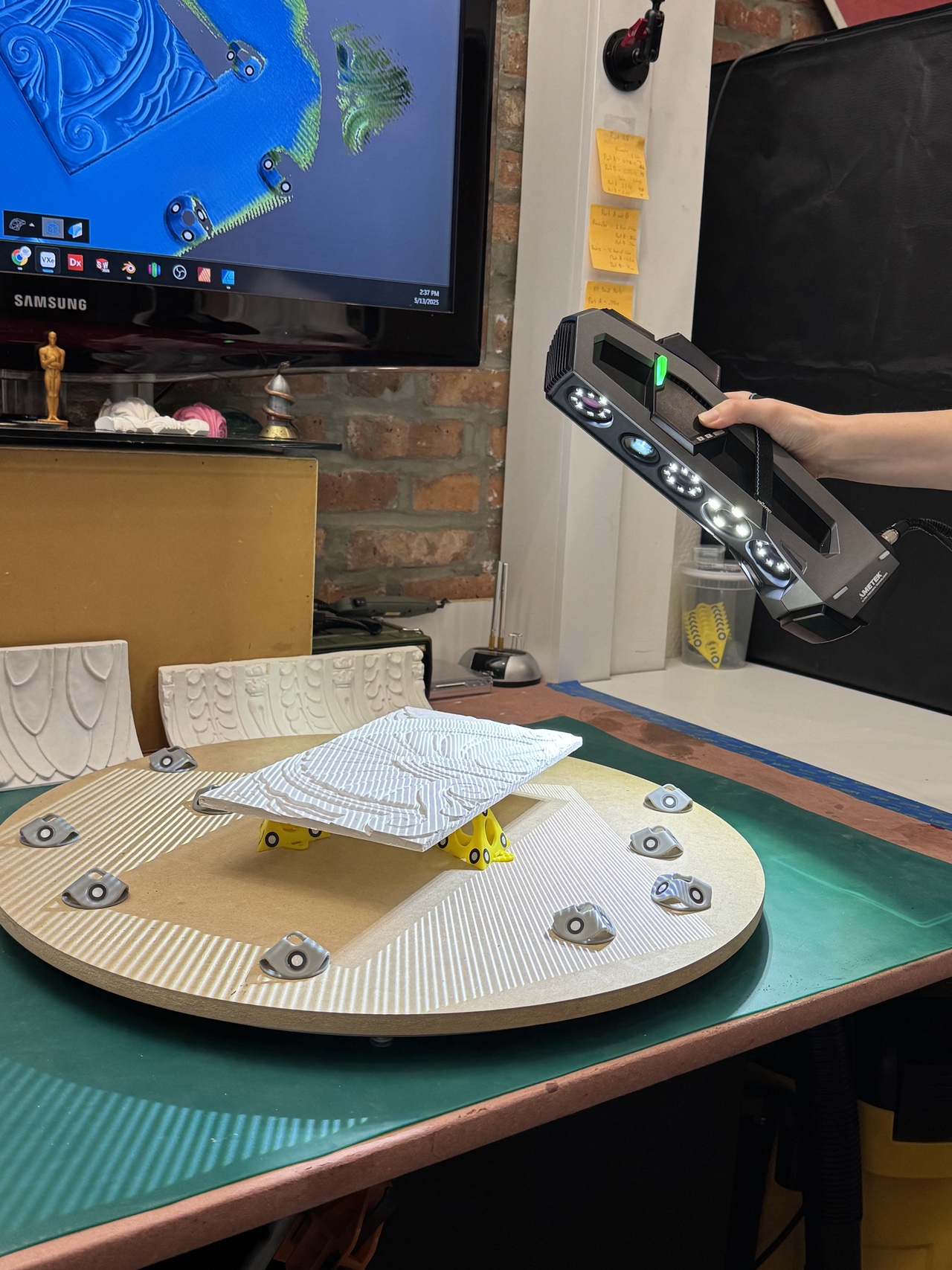

Digital Asset Packages

- High-accuracy 3D scans

- CAD models,

- Render-ready files for campaigns, VR/AR experiences, and digital archiving

Project Workflow

Every project is unique, but the process is grounded in the same principles: we combine 3D scanning, CAD modeling, CNC machining, 3D printing, and casting as needed to deliver the right solution. Below is the general workflow you can expect when working with us.

Discovery

We begin by reviewing your concept, technical requirements, and timeline. This phase ensures we understand the creative intent and the engineering constraints, so we can propose the best path forward.

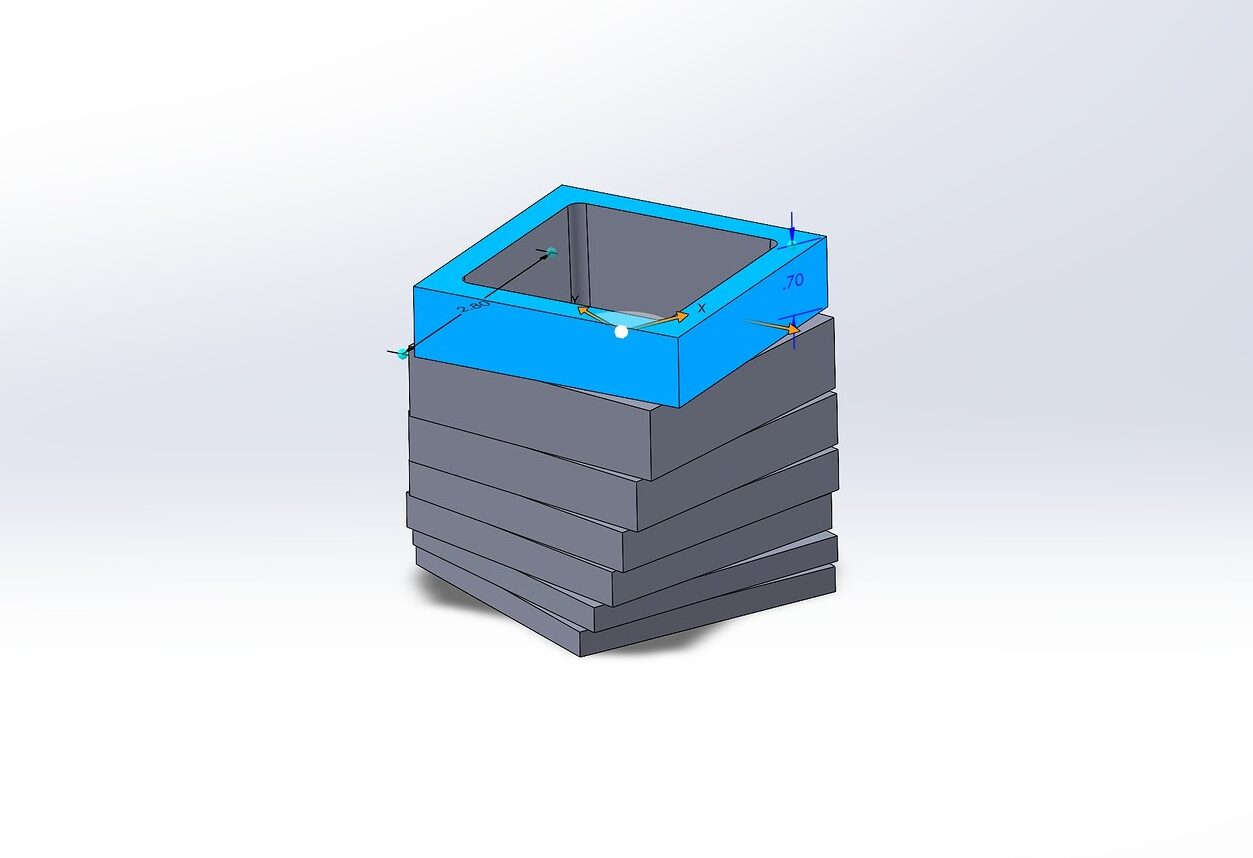

Digital Prep

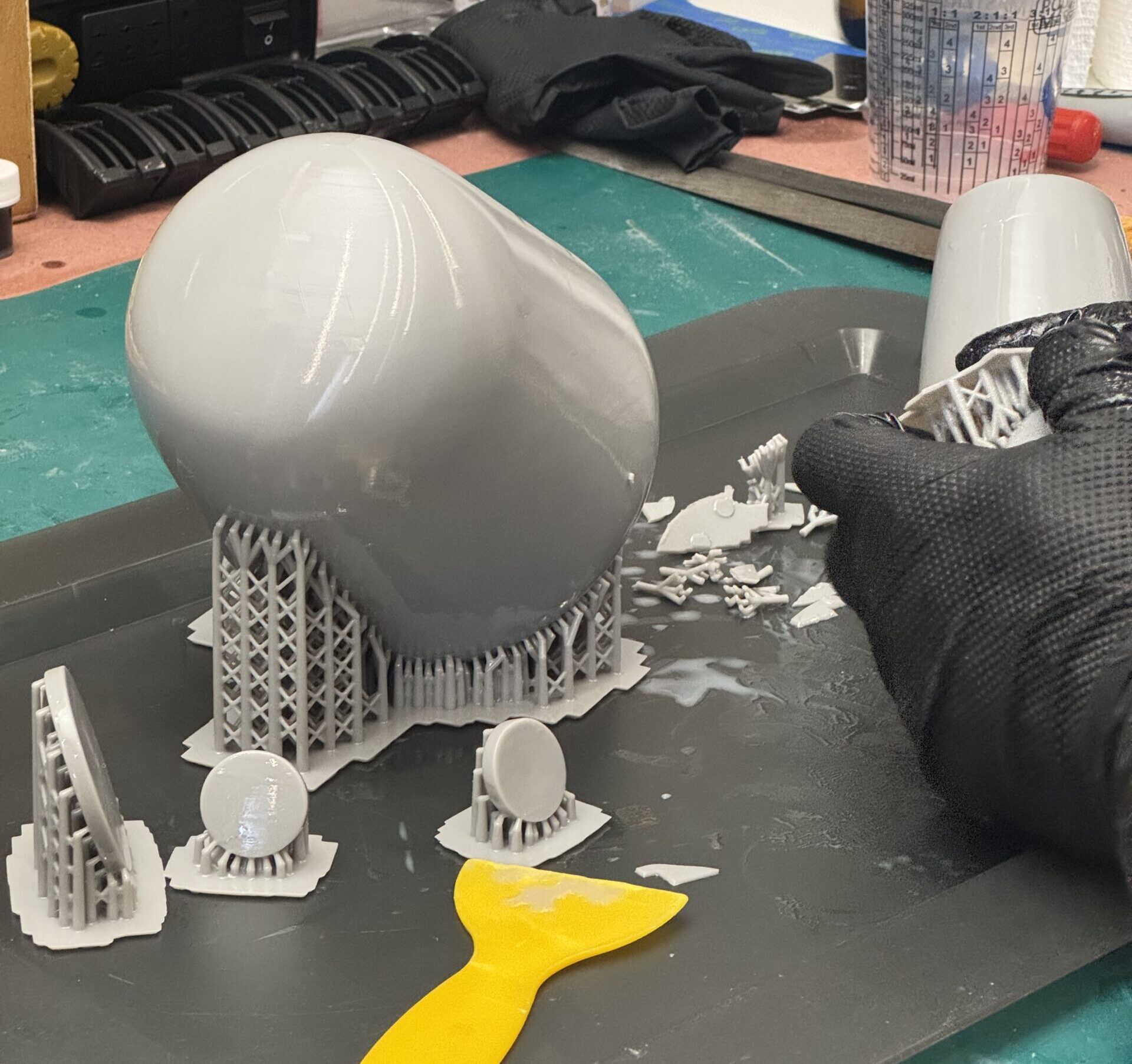

Our team uses 3D scanning, CAD modeling, and file refinement to generate precise digital assets. This foundation allows us to test fit, scale, and design iterations before moving into physical production.

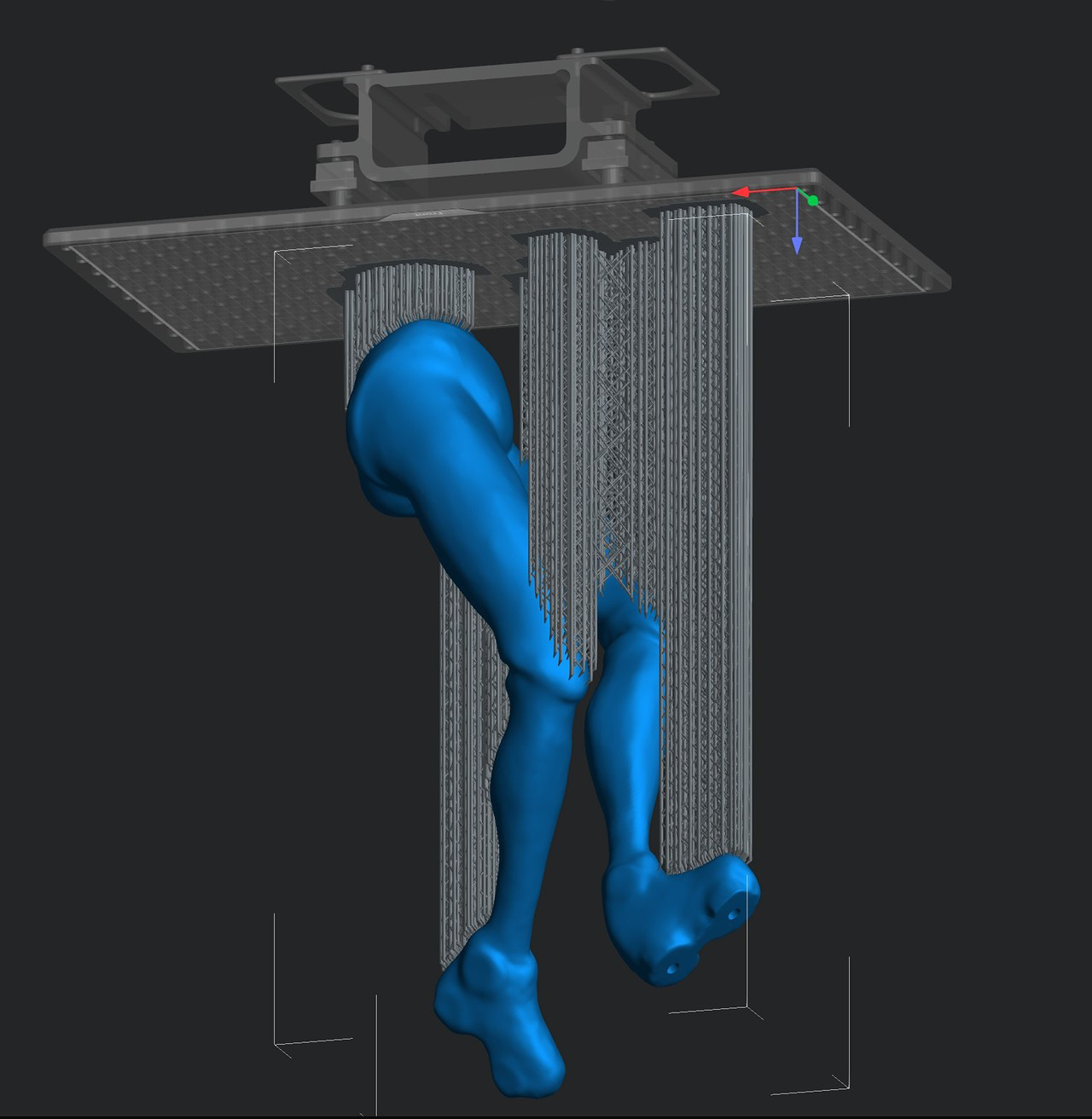

Fabrication

With the digital groundwork complete, we bring your project to life using CNC machining, large-format 3D printing, and casting. Each method is selected to suit the material, scale, and durability your project requires.

Finishing

Every piece is refined with painting, coatings, patinas, sanding, and assembly. This step ensures that your project not only functions as designed but also meets the highest aesthetic standards.

Delivery

We coordinate handoff, shipping, and installation support as needed. Our goal is to make sure your finished piece arrives on-site ready to install, with no surprises on deadline day.

Your Partner in Precision

At Kemperle Industries, we make the complex possible—tackling unusual shapes, tight deadlines, and ambitious creative ideas with confidence. Every build is engineered for precision fit and flawless finish, so your project installs smoothly and looks as good in reality as it did in concept. Our team offers flexible collaboration, whether you need full end-to-end production or support for a single phase, always backed by fast, clear communication and no last-minute surprises. From prototypes and sculptural displays to event builds and brand activations, we deliver custom fabrication with precision and impact.

-

Multi-Industry Expertise – From automotive and marine to art, heritage, and retail, we adapt our workflows to diverse project needs.

-

End-to-End Technology Stack – 3D scanning, CAD, CNC machining, 3D printing, and casting all under one roof.

-

Material Versatility – Wood, metal, plastics, foams, composites, and custom finishes tailored to each project.

-

Trusted Partners – Experienced with institutions, brands, and creatives.

-

Future-Ready Data – Digital files for replication, archiving, or future modifications, ensuring long-term value.

Frequently Asked Questions

Do you handle projects end-to-end, or just certain phases?

Both. We can manage the entire process—from scanning and CAD modeling to fabrication, finishing, and installation—or step in for a single phase if that’s what your project requires.

Can you work with existing design files from our agency or team?

In many cases yes. We can work from existing CAD files, 3D scans, or even basic sketches. Our goal is to make sure your creative intent translates accurately to the final build.

What materials can you fabricate with?

We work across a wide range of materials, including plastics, foams, composites, metals, wood, MDF, and cast materials. We also offer paint, coatings, and patinas to achieve the exact finish you need.

Do you offer installation support?

Yes. We can provide pre-install preparation, assembly, and on-site support to ensure your build installs smoothly and looks flawless on deadline day.

How quickly can you turn projects around?

Timelines vary by scope, but our integrated scan-to-CAD-to-fabrication workflow allows us to move quickly without compromising on quality.