Aftermarket Automotive 3D Scanning & Custom Fabrication in NYC

At Kemperle Industries, we provide automotive 3D scanning, reverse engineering for specialty parts, and aftermarket customizations designed for perfect fit and finish. From our base in New York, we serve the Northeast and beyond—helping custom shops, performance builders, and car enthusiasts create custom car parts with speed, accuracy, and reliability.

Where Accuracy Meets Customization

Our advanced structured light 3D scanners capture your vehicle’s intricate contours and dimensions—inside and out—with unmatched accuracy. That data becomes the foundation for CAD modeling, reverse engineering, and specialized low-volume fabrication.

What We Can Do

Custom Body Kits

Widebody flares, bumpers, spoilers, and other performance styling upgrades built from precision 3D scans for flawless fitment.

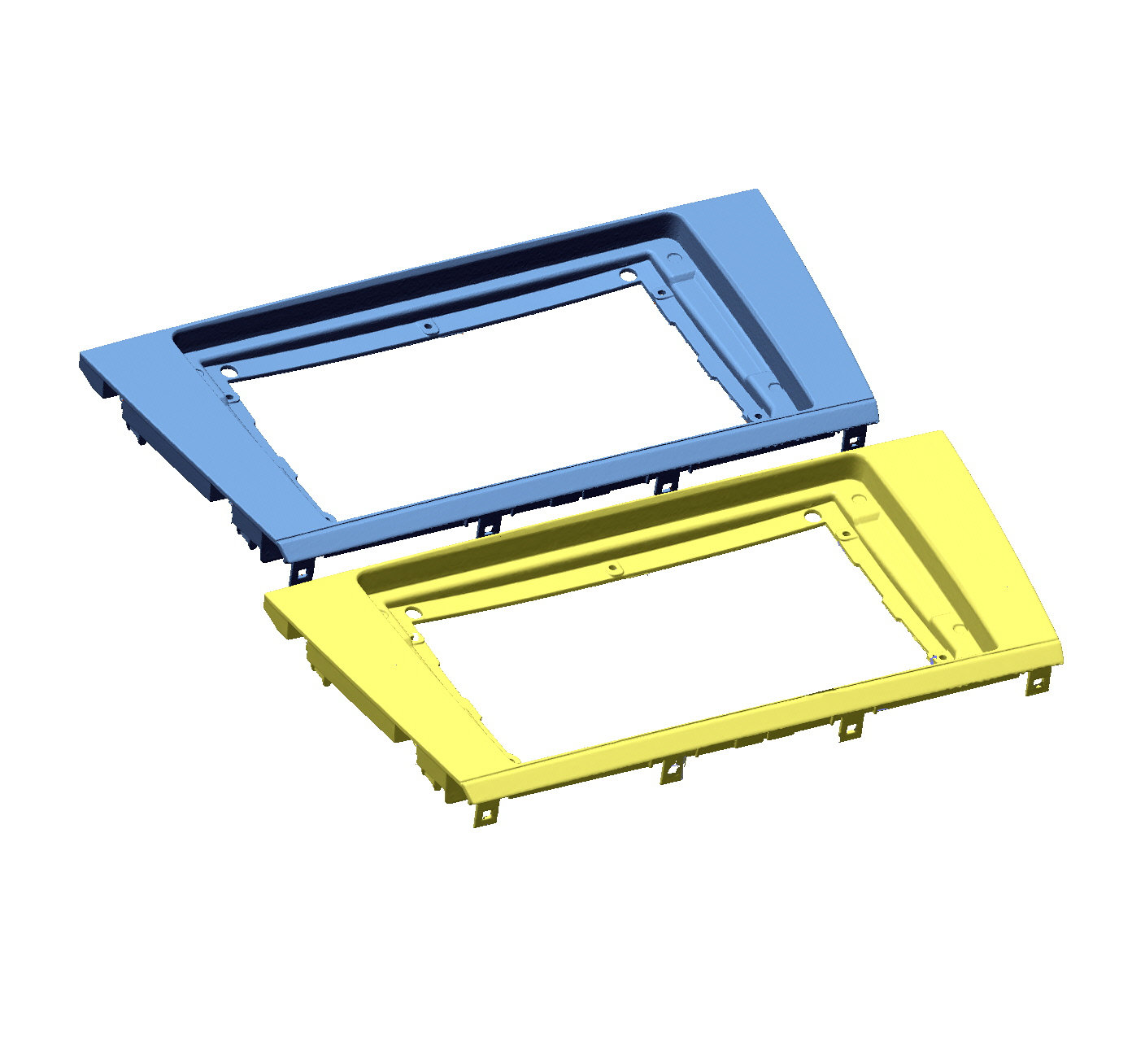

Interior Components & Trim Panels

Dashboards, center consoles, door trims, and emblems designed to match the exact geometry of your interior.

Component Analysis and Reverse Engineering

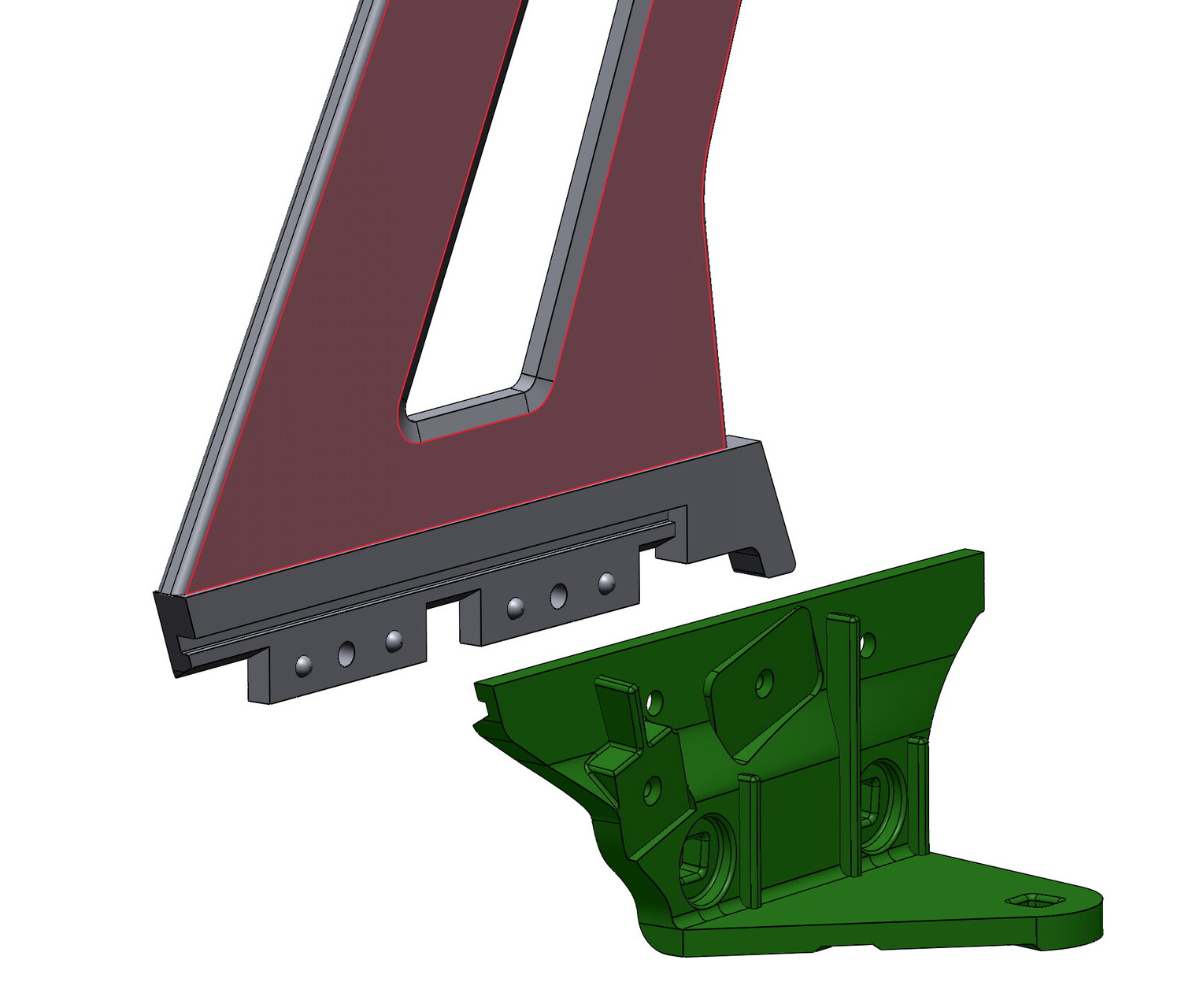

Scanning and modeling of existing automotive parts to create accurate CAD data for replacements, redesigns, or upgrades.

Custom Audio Components

Bespoke panels, mounts, and enclosures engineered through scan-to-CAD workflows for seamless integration and premium sound.

Legacy Part Design & Restoration

Reverse engineer discontinued or damaged components with scan-to-CAD modeling, ready for fabrication or 3D printing.

Performance & Fit Testing

Use high-accuracy point clouds and CAD models to verify fit before fabrication, ensuring parts meet tolerances without guesswork.

Specialized Low-Volume Fabrication

From custom brackets to small-run panels, we produce select low-volume parts in-house, combining CNC machining, molding & casting, and additive manufacturing.

Sample Projects

Our projects highlight the power of our scan-to-CAD workflow in the automotive space. We’ve reverse engineered damaged panels for performance builds, designed and fabricated custom car audio enclosures, and recreated hard-to-find interior components for vintage vehicles. Each project starts with precise 3D scanning and ends with a finished part that delivers accuracy, reliability, and perfect fitment.

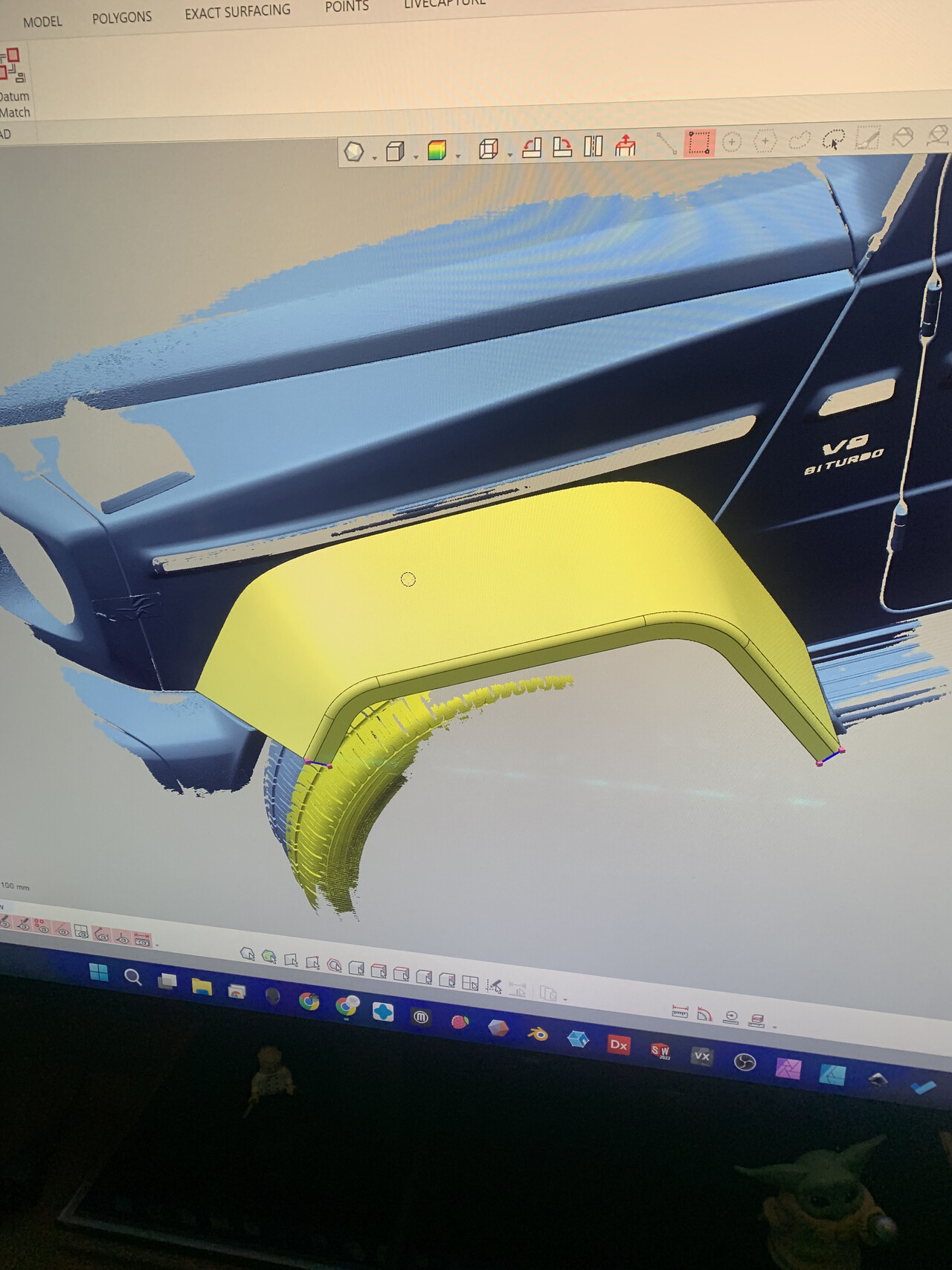

We’ve scanned full vehicle exteriors to design and engineer widebody flares, bumpers, and complete kits. By capturing every contour with sub-millimeter accuracy, our team creates CAD models that integrate seamlessly with OEM geometry. This process ensures panels not only achieve the desired aesthetic but also deliver reliable alignment and long-term durability once installed.

Request a quote

For high-end audio builds, precision is everything. Using 3D scanning, we capture the exact interior geometry of trunks, consoles, and panels to design subwoofer enclosures and custom mounts that blend perfectly with the vehicle. The result is a factory-quality fit with performance-grade sound, eliminating the compromises of off-the-shelf solutions.

Request a quote

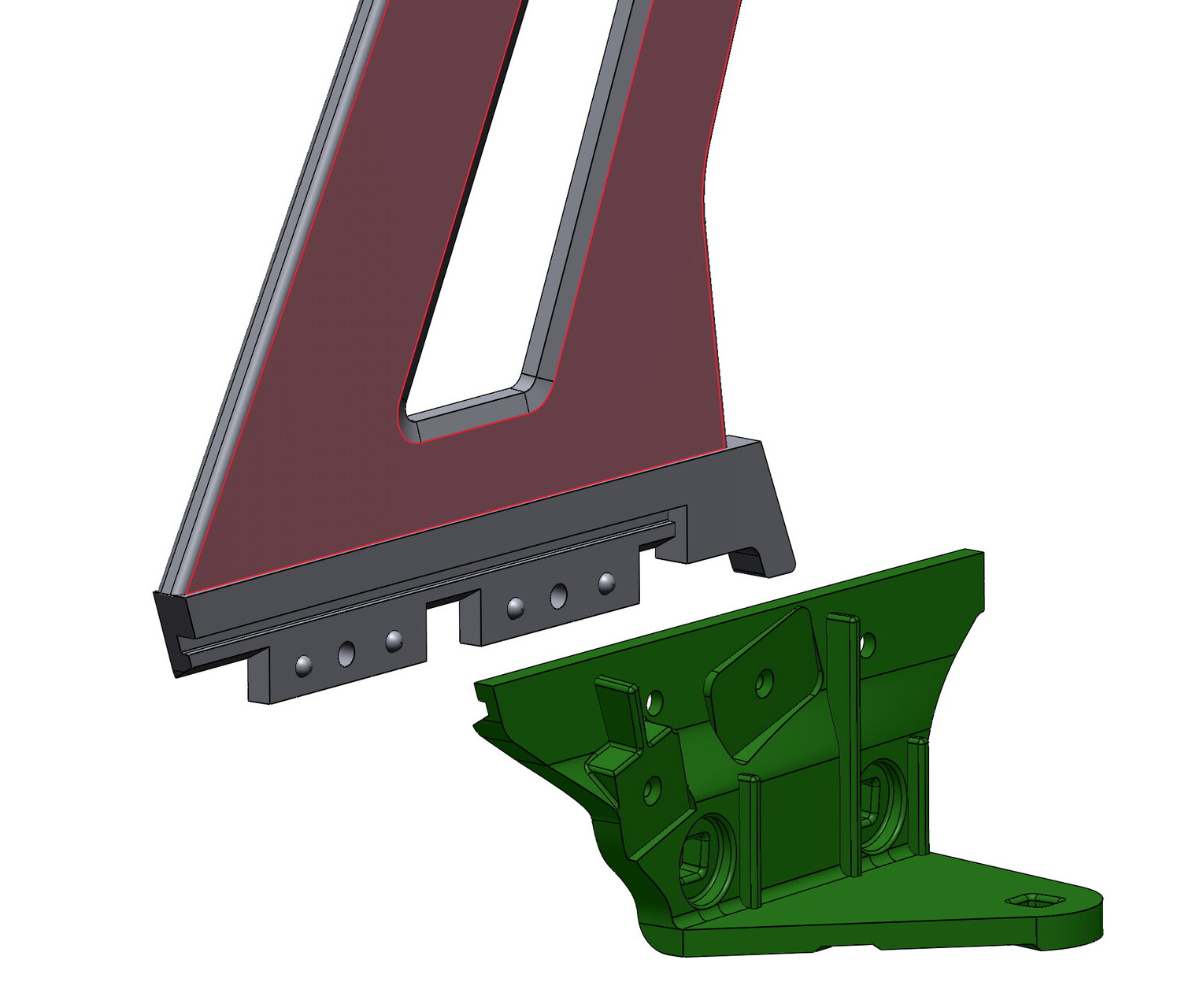

When a part is discontinued or the original documentation no longer exists, we use reverse engineering to bring it back to life. Our workflow starts with scanning the damaged or existing component to create a precise CAD model. From there, we can fabricate replacement parts or provide digital files for machining, casting, or 3D printing—ensuring restorations meet both functional and aesthetic standards.

Request a quote

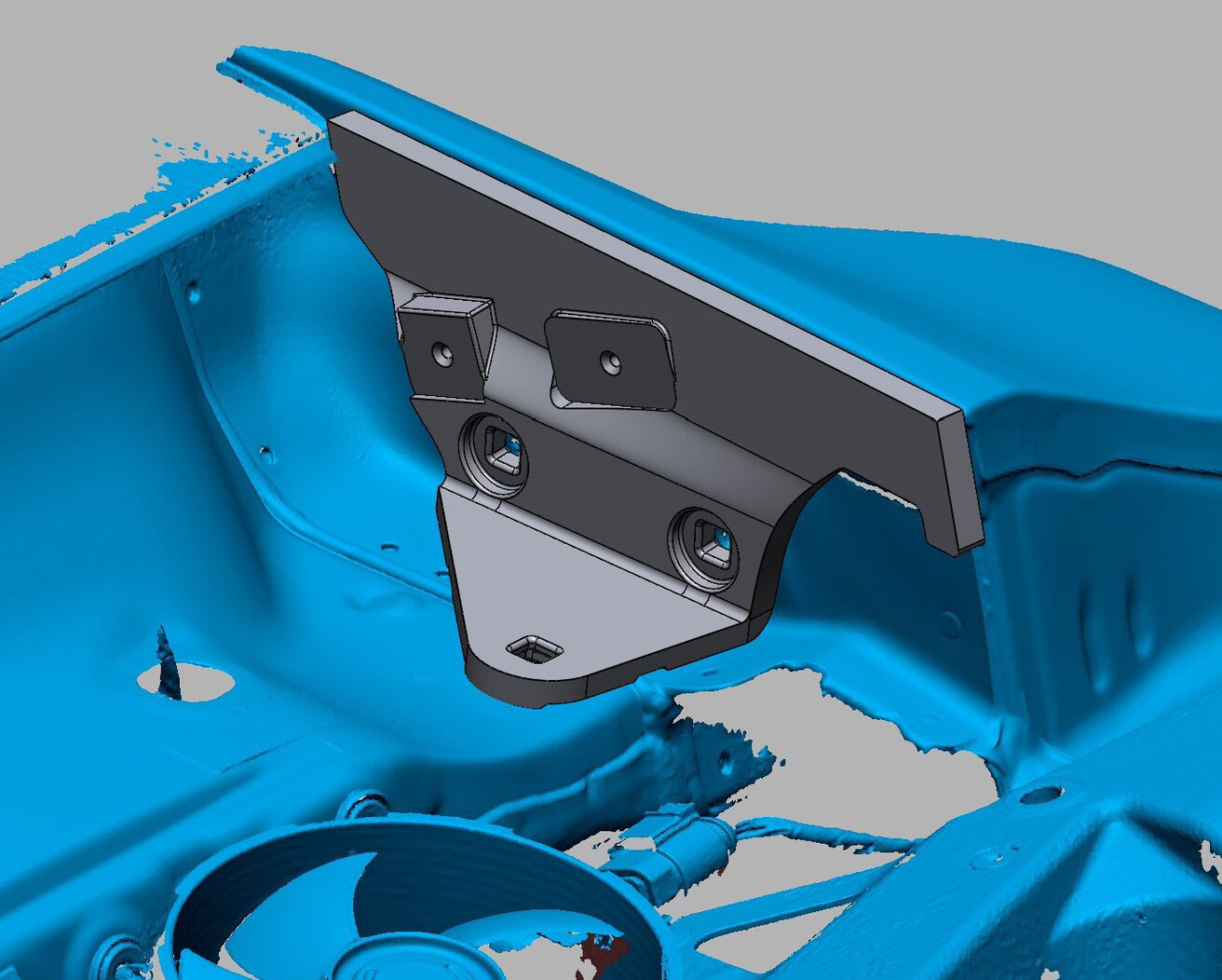

Before investing in fabrication, we use high-resolution point cloud data and CAD overlays to test new components digitally. This process verifies clearances, alignments, and tolerances for performance upgrades such as intakes, mounts, or aerodynamic add-ons. By confirming fitment in advance, we reduce costly trial-and-error and accelerate the path from prototype to installation.

Request a quoteFrequently Asked Questions

Do you provide just the scan data, or finished parts too?

Both. We can deliver raw scan data, CAD-ready files, or fabricate parts in-house depending on your needs.

Can you scan vehicles on-site?

Yes. We provide mobile 3D scanning in New York City and across the Northeast for vehicles, interiors, and specialty parts.

What types of parts do you typically fabricate?

We focus on specialized low-volume parts such as enclosures, panels, brackets, and custom modifications that require precision and tight fitment.