3D scanning is beneficial for supply chains because it helps improve the accuracy and speed of operations while fostering quick delivery and product transport rates. Learn when to use 3D scanning for your project today.

Construction

High-quality scanners enable fast surveying with layout design and site modeling. With rapidly produced and accurate scans, structural designs may be finished sooner than before. In addition to manually-operated devices, 3D scanning technologies can also be used for servicing robots. Rotary-based laser scanners can act as the visual aid for autonomous machines that are operated in sewage pipes.

Consumer Merchandise

Smartphone users can now take precise object scans on a bigger scale. Brand new apps with tablet attachments allow technicians to capture 3D scans of properties which can then be used in home improvement projects.

Military

Military organizations can use 3D scanners to produce custom replacement parts,. This is essential in situations where replacement components are not readily available, or lead times are too long. The U.S. Navy typically takes weeks to fix broken components, but 3D scanners and printers have reduced the time to mere days.

Entertainment And Multimedia

3D scanners are revolutionizing both entertainment and multimedia because they enable the creation of accurate digital models. These models can be used in various projects such as cinematography and video games. In addition to inanimate objects, studios can also use them to scan people and animals to save time and resources. In the past, objects had to be manually created within 3D applications such as 3DS Max, Maya, or Blender. When you need props, costumes, or sets to be made in hours rather than weeks, mobile 3D scanners and CAD are efficient solutions.

Science

Because 3D scanning does not harm the human body, it has a number of scientific uses. A prominent application is manufacturing prosthetics. No two human bodies are exactly the same; prosthetic devices must be tailored to a patient’s unique needs.

Companies are using 3D scans to quickly develop prosthetic parts based on the individual shape of a patient’s body. In the past, prosthetics needed to be made by hand. A single unit could cost thousands of dollars. Thankfully, 3D scanning has helped automate manufacturing processes and lowered the cost to hundreds of dollars.

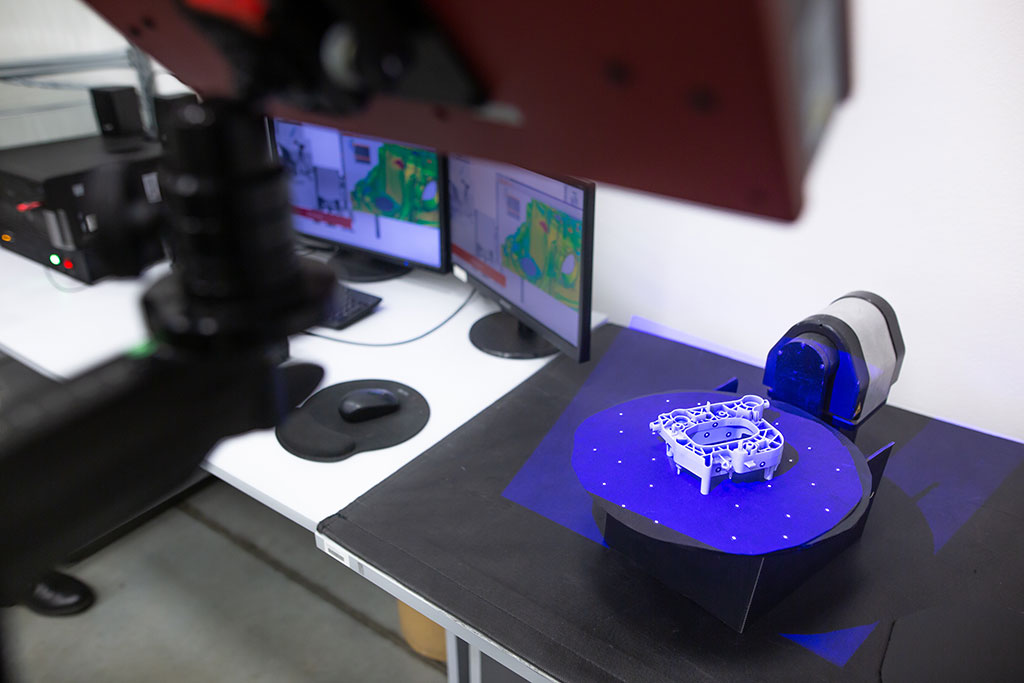

3D scanners can be applied to multiple manufacturing projects across numerous industries. These scanners can be used in any situation where precision and cost efficiency are required. Once a 3D model is made of a specific device, it will be easier for companies to produce custom designs and automate the process. These improvements allow global teams to collaborate and share resources.