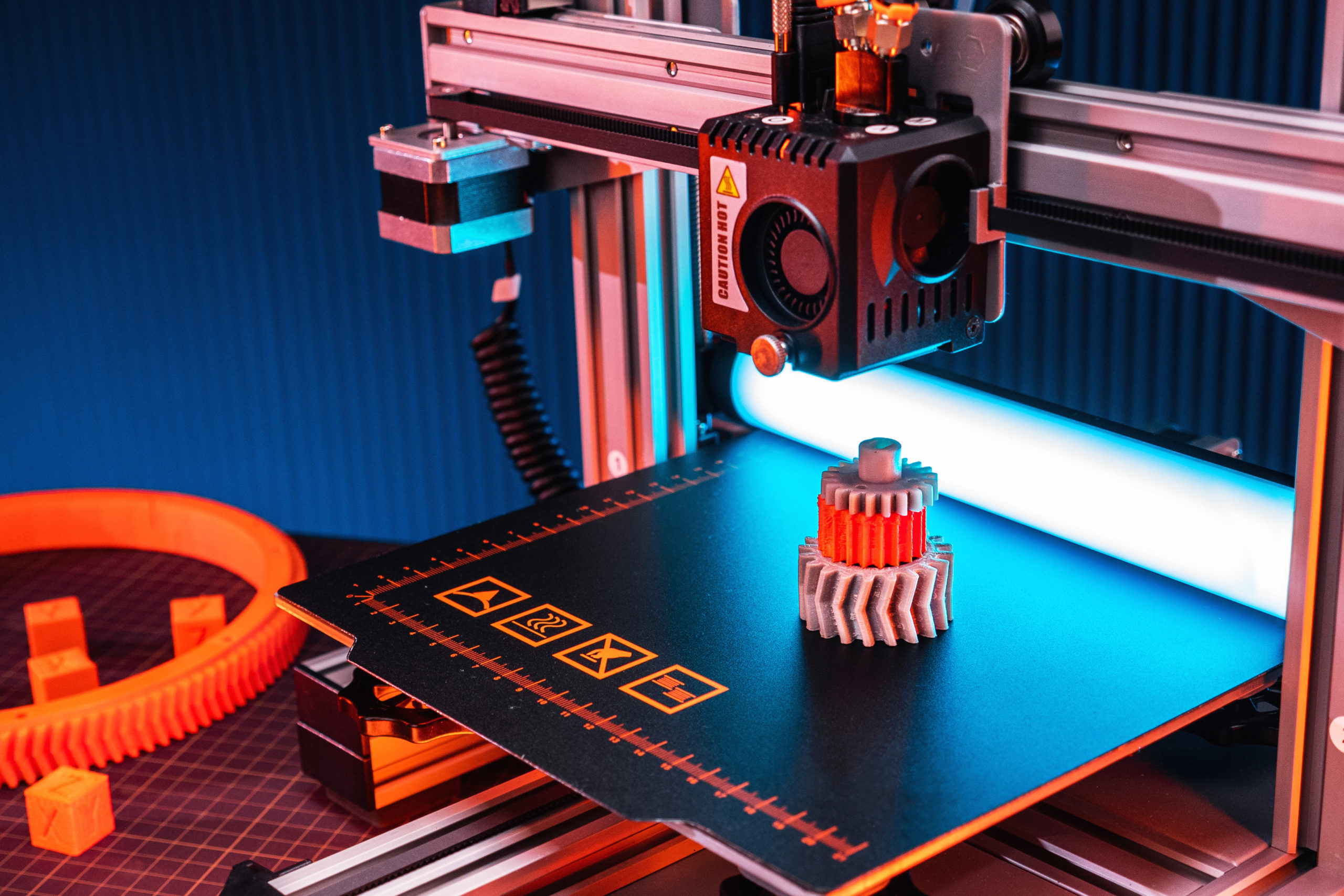

In the rapidly evolving world of product development, 3D printing has emerged as a game-changer, offering unprecedented flexibility and efficiency. From solo inventors in their garages to sprawling corporate design teams, the impact of this technology spans across all scales of production.

Here we explore the top five benefits of 3D printing for product development, demonstrating how it continues to reshape the way products are conceived and created.

1. Speeds Up the Prototyping Process

Gone are the days of waiting weeks for a prototype. With 3D printing, ideas can be brought to life within a matter of hours. This rapid prototyping not only accelerates the design cycle but also allows designers and businesses to iterate faster. Faster iterations mean quicker feedback, and in the long run, a better final product. Imagine tweaking your design over breakfast and testing a new prototype by lunch!

2. Reduces Manufacturing Costs

Traditional manufacturing methods often require expensive molds and setups, especially for intricate parts. 3D printing can offer a cost-effective alternative, particularly for small batch productions. This is a boon for small businesses and startups where budget constraints are a frequent concern. That means more money in the bank for that much-needed coffee machine in your startup’s break room!

3. Enhances Design Flexibility

With 3D printing, complexity comes at no extra cost. Designers are free to explore complex geometries and intricate designs that would otherwise be difficult or impossible to achieve with traditional methods. This freedom opens up new avenues for creativity and innovation, enabling the creation of designs that are not only functional but also aesthetically appealing and unique.

4. Offers Customization at Scale

If personalization is king in today’s market, then 3D printing is its loyal servant. So whether you’re creating custom dental implants or bespoke jewelry, this technology allows for mass customization in ways traditional methods can’t compete. Each item can be tailored to individual specifications without disrupting the manufacturing process, thus providing a significant competitive edge.

5. Sustainable Manufacturing

3D printing can be more sustainable than traditional manufacturing processes. In principle, it uses only the material necessary to create the part, therefore reducing waste. Furthermore, the ability to produce parts on-demand decreases the need for large inventories and minimizes the carbon footprint associated with mass production and transportation.

Adopting 3D printing in product development isn’t just about leveraging new technology. It’s about innovating smarter and staying adaptable in a competitive market. With the advantages of rapid prototyping, cost-efficiency, enhanced design flexibility, and sustainable practices, designers and businesses are far more empowered to push creative boundaries and achieve more sustainable production methods.

Interested in integrating 3D printing into your product development cycle? We’re here to help. Contact us for a consultation and let’s bring your ideas to life!