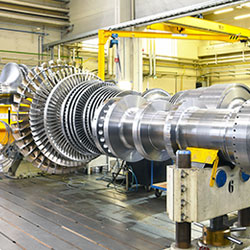

We work with clients on a variety of specialized manufacturing projects. Whether you are looking to manufacture complex mechanical components or simple everyday objects, it is important to work with a company that can provide you with the right solutions for your project. You can turn to Kemperle Industries with confidence knowing that our ability to seamlessly integrate into your project will ensure a smooth and successful outcome for your project. We understand the challenges associated with any type of manufacturing project, so let our experience keep you on the track to success.

Manufacturing Low-Volumes of Products

Today, businesses are increasingly turning to low-volume specialized manufacturing for the benefits it brings. As a bespoke service that produces parts and components limited to small volumes, low-volume manufacturing allows for more diversification in the beginning of the production process. Most places bind you to very long, and high volume commitments. At Kemperle Industries no such limitation is put in place. Need just 5, 10, 100 items assembled? We have you covered with zero long-term or large volume commitments.

Businesses may wish to get a limited number of parts produced for prototypes that are not ready for full-scale production. Small-volume specialized manufacturing can cater to products with shorter life cycles, as well as reduce cost and unnecessary waste. It may be an ideal option for businesses that want to create prototypes before committing to full-scale production

Request a quoteOur Specialized Manufacturing Pipeline

When you approach us for specialized manufacturing, below is a sample of what to expect during the Product Evaluation Process:

Introduction

The precursor to any project. Here we discuss how our process works and what you can expect by working with us. We use this time to answer any questions and ensure that you have a full understanding of what lies ahead.

Data Collection

Here we create a repository documenting everything about your product and its manufacturability. Everything from the component count, materials used, quantity of parts, and overall functionality are thoroughly documented in order to prepare for the analysis stage.

Data Processing & Analysis

During this stage we take everything from the data collection stage and begin to analyze and sort it. We figure out where components will be sourced and manufactured, as well as discover any possible problems that may need addressing prior to manufacturing.

Address Known Issues

With the data gathered from the previous phase we layout a roadmap designed to address any issues on concerns that we have found. This can include anything from DFM problems to material sourcing, and even something as simple as a no longer available screw.

Apply Findings

Once all the known issues are addressed and planned for, we apply the rest of our manufacturing strategy in order to prepare for the final stage. Once everything is accounted for, we can begin the final stage of your manufacturing project.

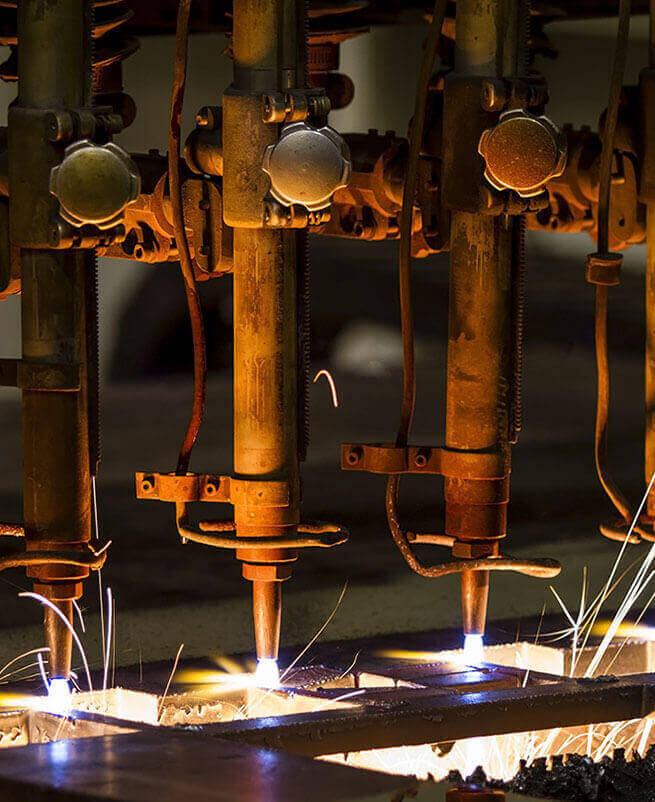

Execute Manufacturing

The final step, your project has reached the manufacturing stage. During this stage we will meticulously assemble your product and provide you with frequent status updates until the project is completed. Once complete all assets will be handed over concluding the project.

Optional Life Testing Program

This is a fundamental but often overlooked aspect of any product development project. If you choose to proceed with this phase, a comprehensive testing plan will be designed in order to ensure any long-term issues are found and addressed prior to large scale manufacturing.

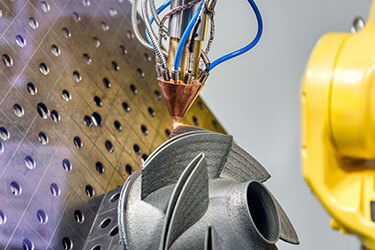

How We Proceed

Low-volume specialized manufacturing is typically considered a faster process when compared to traditional high-volume manufacturing. However, that does not mean the process is not thorough or introduces its own set of challenges. Understanding not only the form and function but also the methodology behind the design is key to successfully executing any project. Because of the lower volume involved, it allows businesses to test out prototypes or production designs in lower volume before proceeding with mass production. In some cases, mass production is completely avoided due to the inherent nature of the project. When your specialized manufacturing project is ready to proceed, you will be kept up to speed on the following as the project progresses:

● Time frame, and design analysis.

● Materials and processes used for various components.

● The inspection and verification of components and sub-assemblies.

● Life testing requirements for components and sub-assemblies.

● Suggested design alterations to components and sub-assemblies.

● The methodology used in determining the best approach to assembly.

● Detailed analysis of any packaging design and requirements.

Why Choose Kemperle Industries?

If you require low-volume specialized manufacturing services, Kemperle Industries is a reliable partner who will work closely with you to understand your goals and vision and ensure that product specifications do not fall short of your expectations. Our experience and expertise in smart engineering and creative design enable us to deliver the solutions you need.