Design and Engineering Services in New York City

For Product Development and Manufacturing

Kemperle Industries provides integrated design and engineering services, supporting clients from early concept through rapid prototyping and full 3D fabrication service workflows. We transform ideas and physical references into production-ready digital models, then move seamlessly into prototyping, testing, and manufacturing using additive and subtractive processes.

→ Start a design project

→ Explore our 3D fabrication services

What Are Design & Engineering Services?

Design & engineering is the foundation of successful product development. It is the process of translating ideas, requirements, and physical references into accurate, manufacturable digital models that can be produced reliably and repeatedly.

At Kemperle Industries, design and engineering is tightly integrated with 3D scanning services, reverse engineering, 3D printing services, and CNC machining, allowing us to solve problems that traditional design studios cannot. We don’t just design parts—we design them to be made.

Our services are used by startups, manufacturers, artists, and institutions that need:

-

- Functional prototypes that behave like real parts

-

- Production-ready CAD models

-

- Designs optimized for additive or subtractive manufacturing

-

- Faster iteration without costly rework

Product Development Pipeline

Ideation

We begin by defining goals, constraints, performance requirements, and manufacturing considerations. This stage includes technical consultation, requirement gathering, and feasibility analysis to ensure the concept is grounded in real-world production from the start.

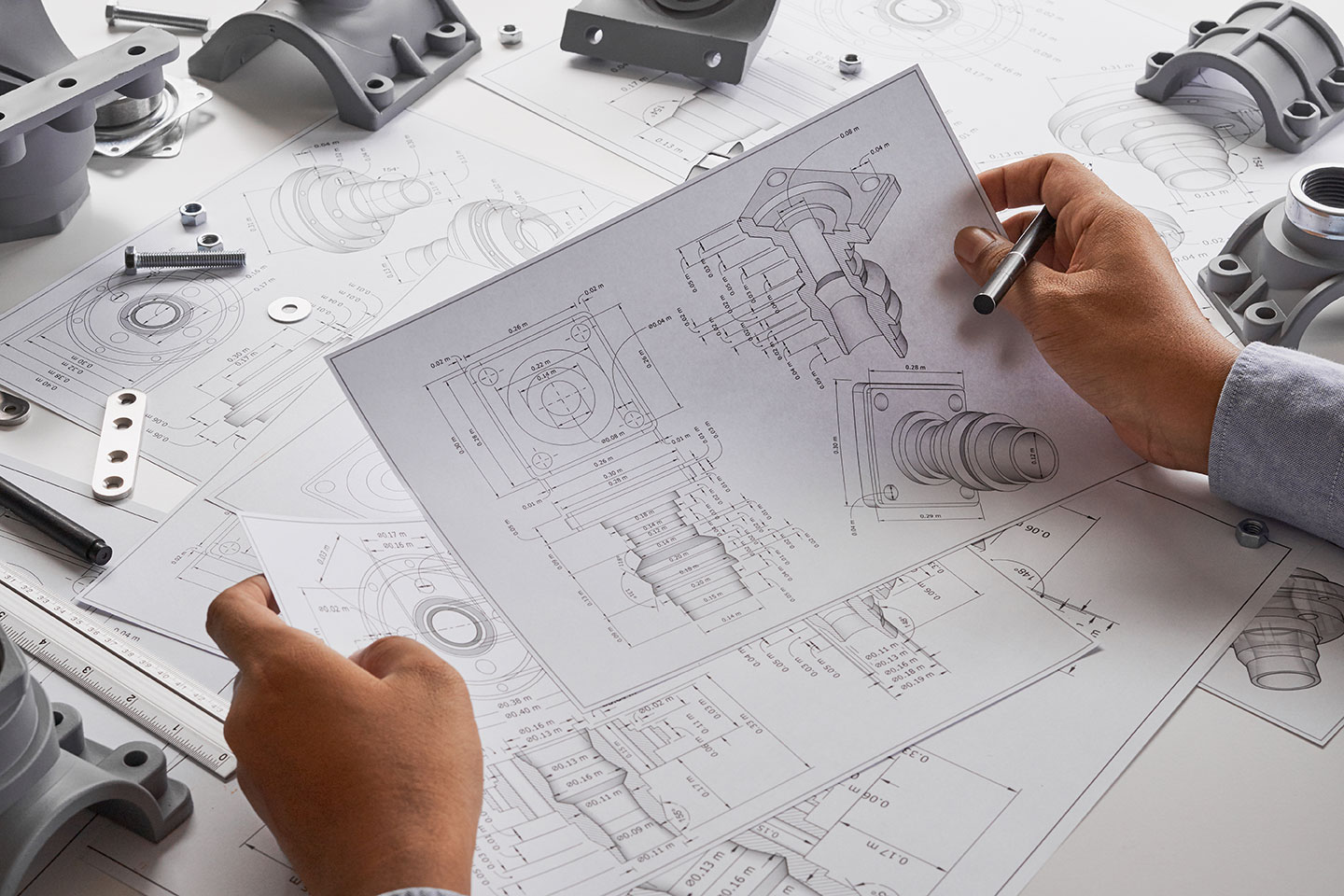

Drafting

Initial layouts and technical drafts are created to explore scale, geometry, interfaces, and constraints. Drafting establishes the foundation for accurate CAD modeling and identifies potential issues before detailed engineering begins.

Concept Sketching & CAD Design

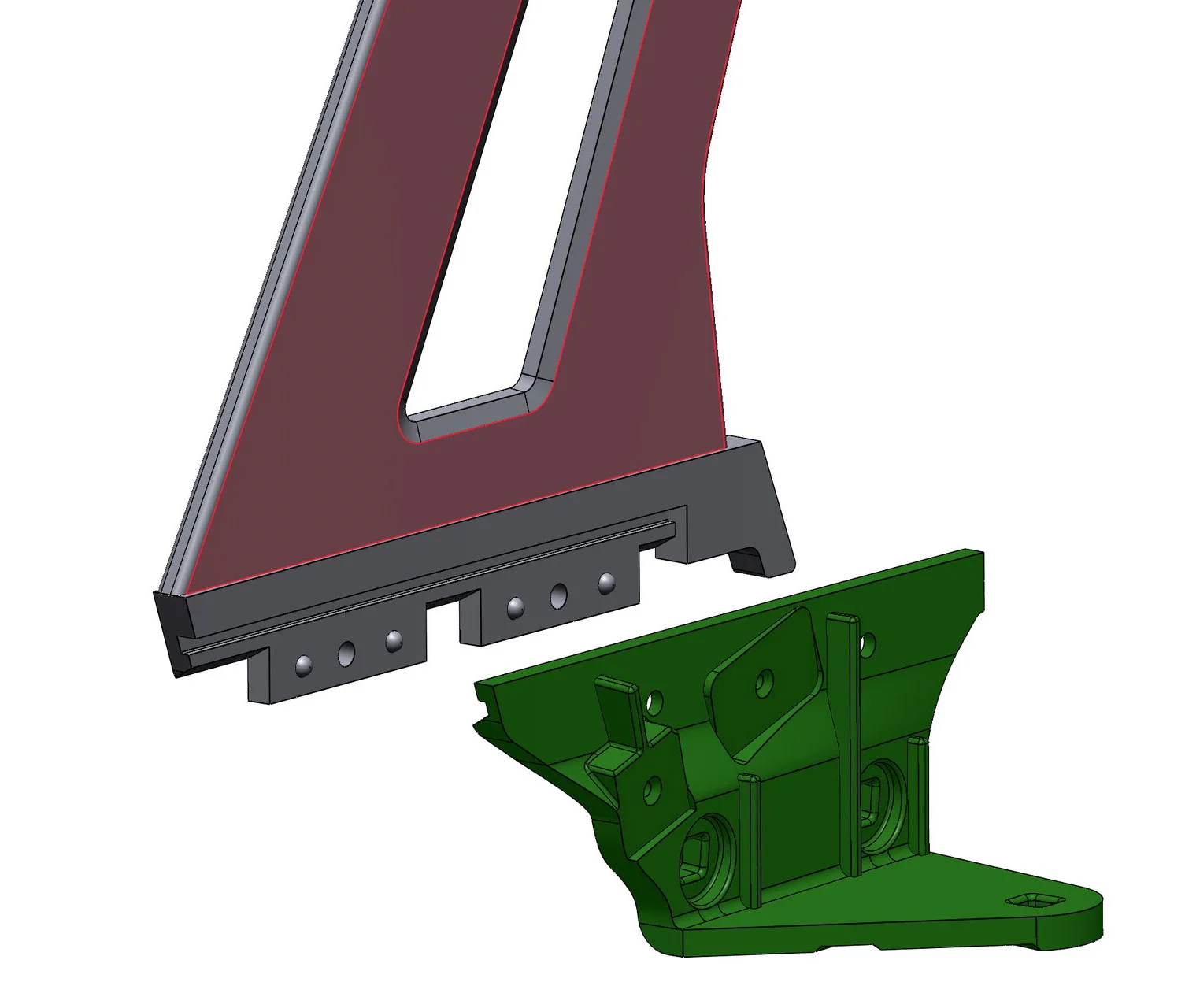

Concepts are translated into detailed 3D CAD models using industry-standard design software. At this stage, we refine geometry, assemblies, and interfaces while preparing the design for rapid iteration and prototyping.

When projects begin with physical parts, we integrate 3D scanning services to capture existing geometry and convert it into editable CAD models.

→ Learn more about 3D Scanning Services

Prototyping

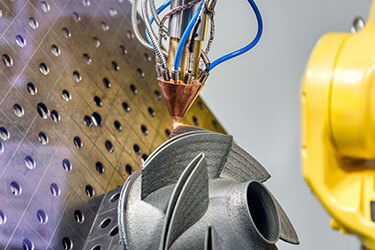

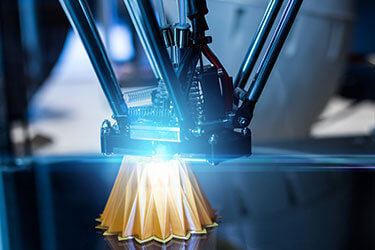

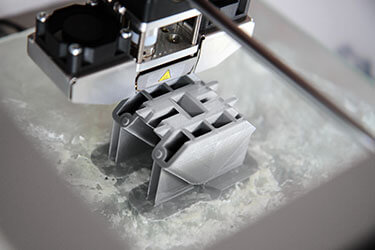

Designs are validated through rapid prototyping using 3D printing services or CNC machining, depending on performance and tolerance requirements. Prototypes are used to evaluate fit, function, assembly, and user interaction early in the process.

→ Explore 3D Printing Services

→ Explore CNC Machining Services

Evaluation & Testing

Prototypes are evaluated under real-world conditions to identify areas for improvement. This may include functional testing, assembly testing, and user feedback. Findings are incorporated back into the CAD model for refinement.

Industrial Design & Design For Manufacturing

At this stage, designs are optimized for manufacturing (DFM), efficiency, cost, and reliability. We refine wall thickness, tolerances, material selection, and geometry for additive or subtractive production, ensuring smooth transition from prototype to manufacturing.

Life Testing & Final Beta Prototype

Final beta prototypes are produced and tested under simulated use conditions to validate performance, durability, and longevity. This stage ensures that the design is production-ready and meets functional expectations before full manufacturing begins.

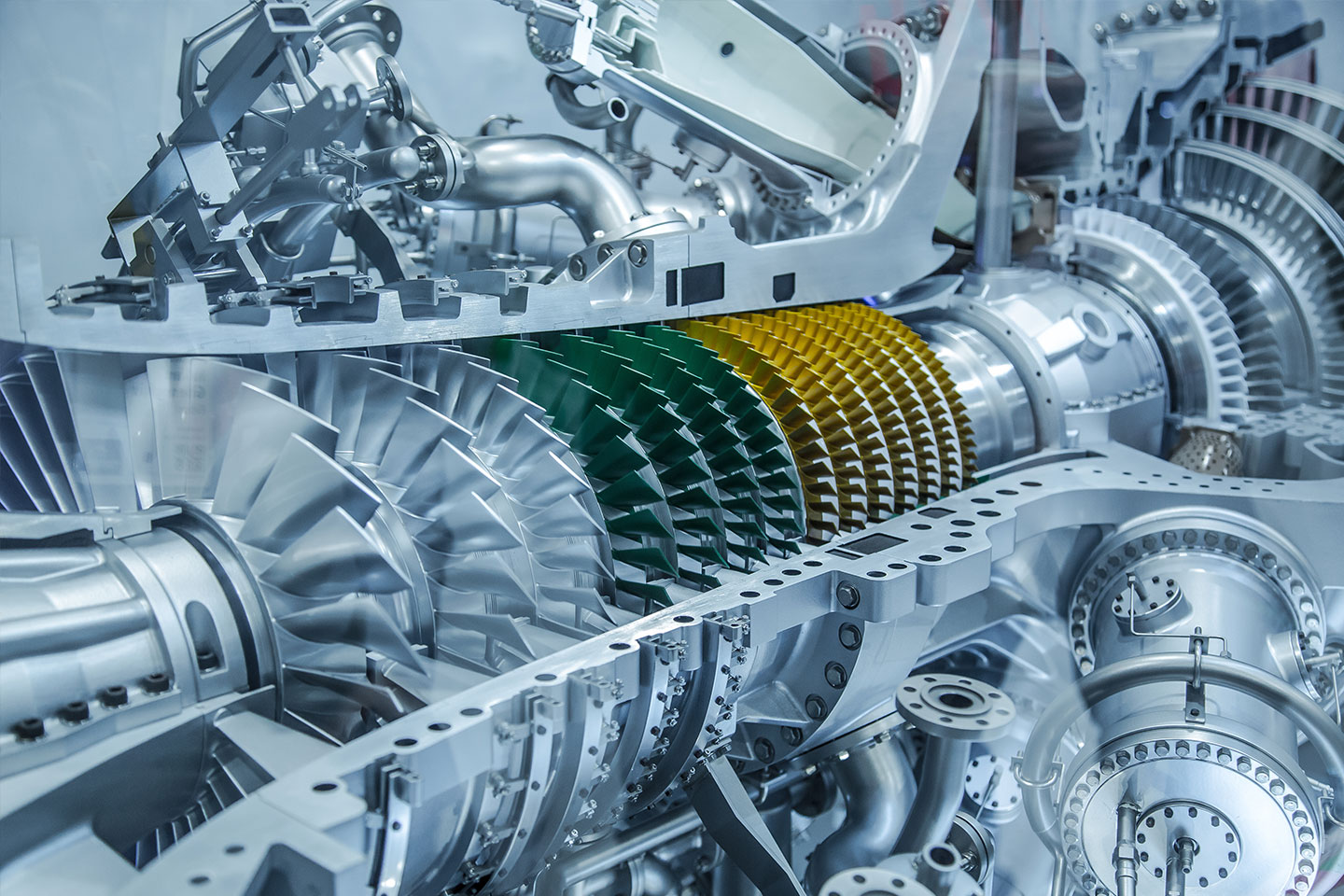

Manufacturing

Once validated, designs move into production. We support manufacturing through our integrated 3D fabrication services, including 3D printing and CNC machining, or deliver complete manufacturing-ready files to your chosen production partner.

Engineering Capabilities for Manufacturable Product Design

Our design and engineering services are built around one core goal: creating products that can be prototyped, tested, and manufactured reliably. Every capability below supports a specific stage of product development, from early concept through production and long-term support.

Unlike design-only studios, our engineers work in direct coordination with 3D scanning services, 3D printing services, and CNC machining, ensuring that design decisions translate cleanly into physical results.

We design mechanical components and assemblies that balance function, performance, and aesthetics, ensuring parts are ready for real-world use. Our industrial design process integrates ergonomics, material behavior, and manufacturing constraints from the start.

This is especially important for products that will be:

-

Rapidly prototyped using 3D printing services

-

Produced as functional parts through CNC machining

-

Integrated into existing assemblies captured through 3D scanning services

Designing for manufacturing means accounting for material behavior, tolerances, process limitations, and repeatability long before production begins. We optimize designs for both additive and subtractive manufacturing, ensuring parts scale smoothly from prototype to production.

Our engineers routinely adjust geometry for:

-

FDM, SLA, SLS, and MJF printing workflows

-

CNC machining tolerances and toolpaths

-

Hybrid workflows (print → machine/mold → finish)

We use simulation and testing to reduce risk and validate design decisions before fabrication. This includes 3D simulation for fit and interference, as well as system-level analysis for assemblies and multi-part interactions.

Simulation is paired with physical testing using rapid prototyping through 3D printing services or machined test parts, allowing digital and physical validation to work together.

Request a quote

Many products fail not because individual parts are wrong, but because systems don’t integrate cleanly. We engineer interoperable systems that account for interfaces, tolerances, assembly order, and long-term serviceability.

This includes:

-

Multi-part mechanical assemblies

-

Modular product architectures

-

Integration with scanned legacy components

-

Compatibility with existing OEM systems

We often begin these projects with 3D scanning services to capture real-world geometry and ensure new designs fit the first time.

Request a quote

Products evolve. We provide ongoing design optimization and sustaining engineering support for products already in production, helping clients improve performance, reduce cost, or adapt to new materials and manufacturing methods.

Common use cases include:

-

Updating designs for new 3D printing materials

-

Improving strength or durability

-

Simplifying assemblies for manufacturing

-

Supporting long-term production runs

This work often connects directly to CNC machining and 3D printing services for iterative improvement.

Request a quote

We support life testing and durability validation for products that must perform over time. This includes iterative testing, failure analysis, and redesign to ensure products meet real-world demands before scaling production.

Final test parts are often produced through 3D printing services or CNC machining depending on material and tolerance requirements.

Why Choose Kemperle Industries?

Kemperle Industries is a New York City–based design, engineering, and 3D fabrication studio that supports projects from concept through production. Our team combines 3D scanning, reverse engineering, rapid prototyping, 3D printing, and CNC machining into a single, coordinated workflow—so designs move efficiently from digital models to finished parts without unnecessary handoffs.

We work with clients across automotive, marine, industrial manufacturing, architecture, and art fabrication who need accurate geometry, tight tolerances, and manufacturing-ready results. Our local NYC presence allows for hands-on collaboration, fast turnaround, and on-site support when needed.