There’s no doubt that it takes time to achieve optimal results with 3D scanning. As you acquire more experience working with the technology over time, naturally you will start to develop mindfulness of the best practices to follow when it comes to achieving the best scans. Here will share with you some top tips in this article.

Preparing the Environment

Regardless of which 3D scanning method you are using, with the exception of contact scanning, you will need to prepare the surrounding environment. For instance, if you are sitting next to the object while it’s being scanned, part of you may end up being scanned as well. Preparations include removing any other objects in the vicinity and minimizing any external disruptions which can affect your scan results.

Preparing the Object

If you’re going to scan something like a car there are a few steps you can take in order to make the process simpler down the road. Ensuring the surrounding area is clear for easy movement around the vehicle is key. Cleaning the surface of the car is also important since modern day scanners pick up so much detail they can capture dirt and grime located on the surface of the vehicle.

When making use of other methods to scan transparent, shiny, or dark objects, you will want to consider coating it with something like a 3d scanning spray. The best of these sprays are so good that they sublimate over time essentially eliminating any cleanup you might need to do. Always remember to apply a light coat as too much can result in dripping that will then show up in the scans.

Calibrating Your Scanner

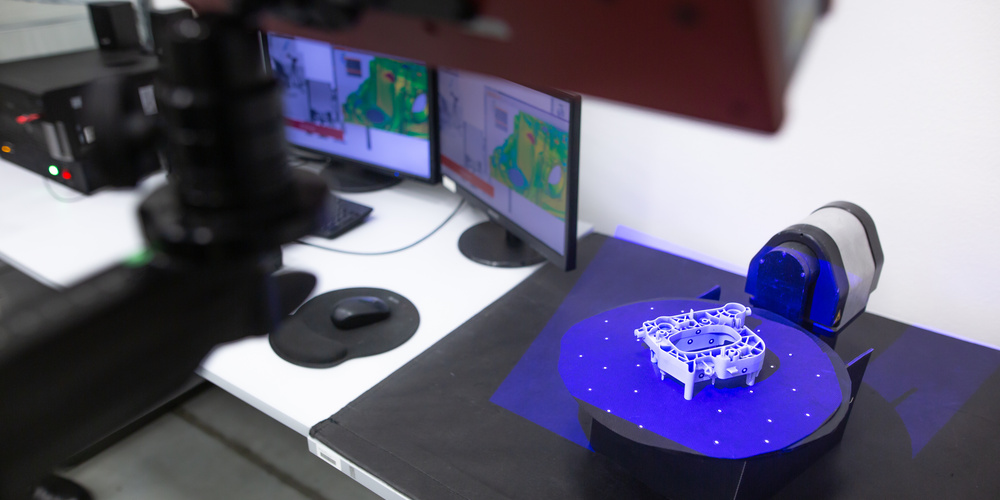

The first thing to do before starting any scanning project is to calibrate your equipment. This is essential to ensure your equipment is running in its optimal state. You need to take into consideration the environmental factors you are scanning in as well as the equipment settings. This will include the rotation and position of the scanning equipment in relation to the object being scanned.

One way you can check if your calibration is accurate is by scanning an object with measurements you already know. If the results you get match the known measurements, then you will know your scanner has been calibrated correctly.

Scanning the Object

If you are looking to do a complete 3D scan, capture the object from different angles, keeping in mind that they can be merged and aligned at a later point. In order for multiple scans to be aligned with each other, they will need common features so always ensure that you get enough coverage.

Cleaning Up the Scans

Remember: there’s no such thing as a perfect 3D scan, and you will find that there’s almost always a defect in each scan. The key here is to minimize these defects as much as possible. Outlying points and noise can always be smoothed over or deleted through the use of a scan processing program.

In addition, you can easily merge scans after they have been aligned before triangulating them. From here, you can simply remove any excess, unwanted data. If your 3D scanning device comes with this feature, you can also add texture to the final mesh during this stage.

For any more questions about 3D scanning, feel free to check out our FAQ or contact us directly!