3D scanning technology has revolutionized numerous industries by providing detailed digital representations of physical objects. Whether using structured light scanners or laser scanners, the data captured is vital for a variety of applications. Here we delve into the various types of 3D scan data and how these data forms are utilized across different sectors.

Understanding the Primary Data Outputs of 3D Scanners

3D scanners typically produce three main types of data formats:

- Point Clouds: Collections of vertices representing the surface geometry of the scanned object.

- Meshes: Networks of polygons connecting the dots from a point cloud to form a 3D shape.

- Texture Maps: Capture the surface color and texture, enhancing visual realism.

Additional Types of 3D Scan Data Outputs

Beyond basic geometric representations, 3D scanners can also provide:

- Normal Maps and Displacement Maps: Store detailed surface texture and depth, crucial for adding realism in visual effects.

- Reflectivity and Glossiness Maps: Used for recreating surface interactions with light, essential for realistic rendering.

- Volumetric Data: Used in fields like medicine, representing both the surface and internal structure of scanned objects.

Applications of 3D Scan Data Across Industries

The versatility of different types of 3D scan data allows for broad applications:

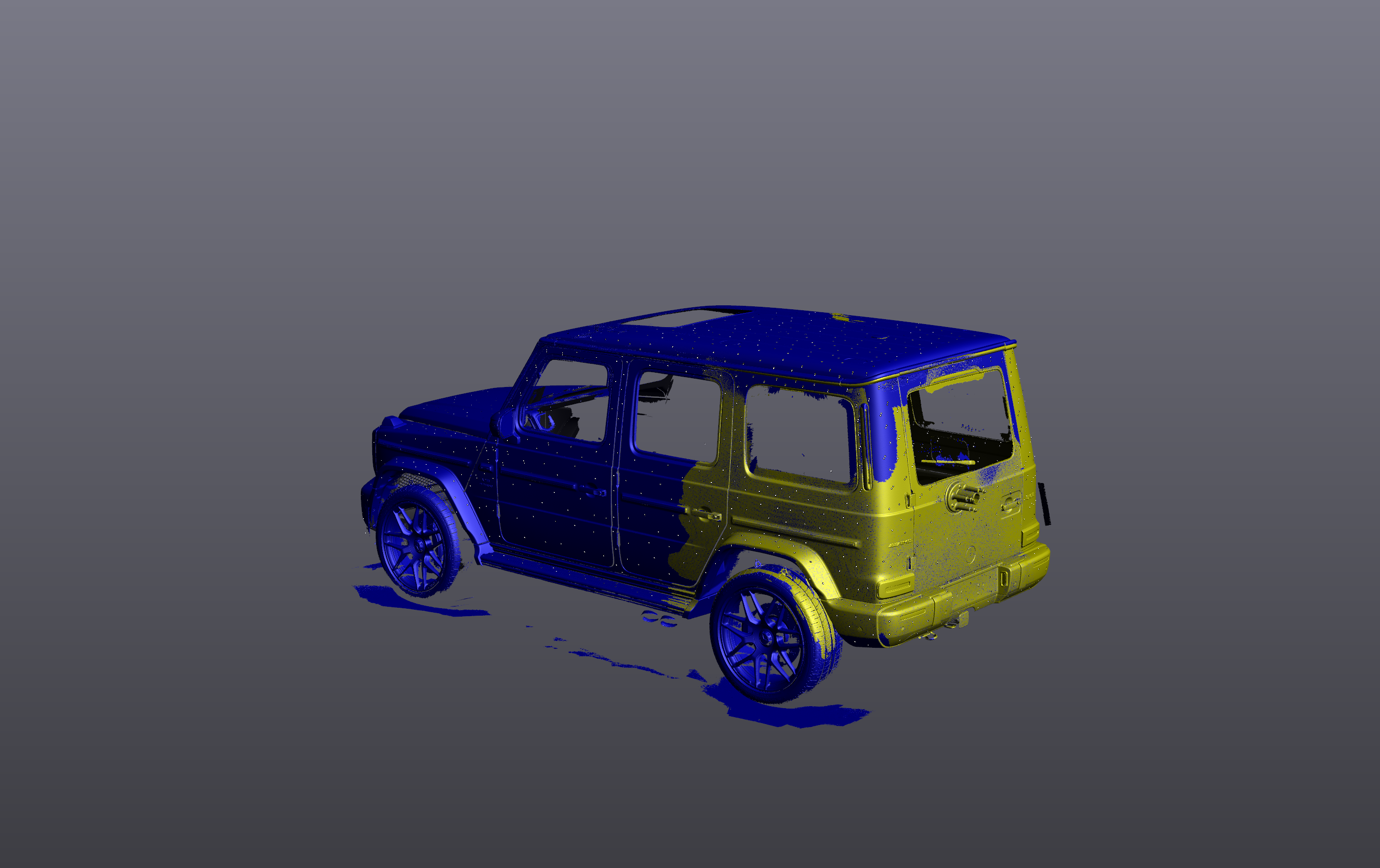

Automotive: Engineers in the automotive industry use CAD models and texture maps for designing new components and customizing vehicles.

Scan sections of a Mercedes-Benz G Wagon

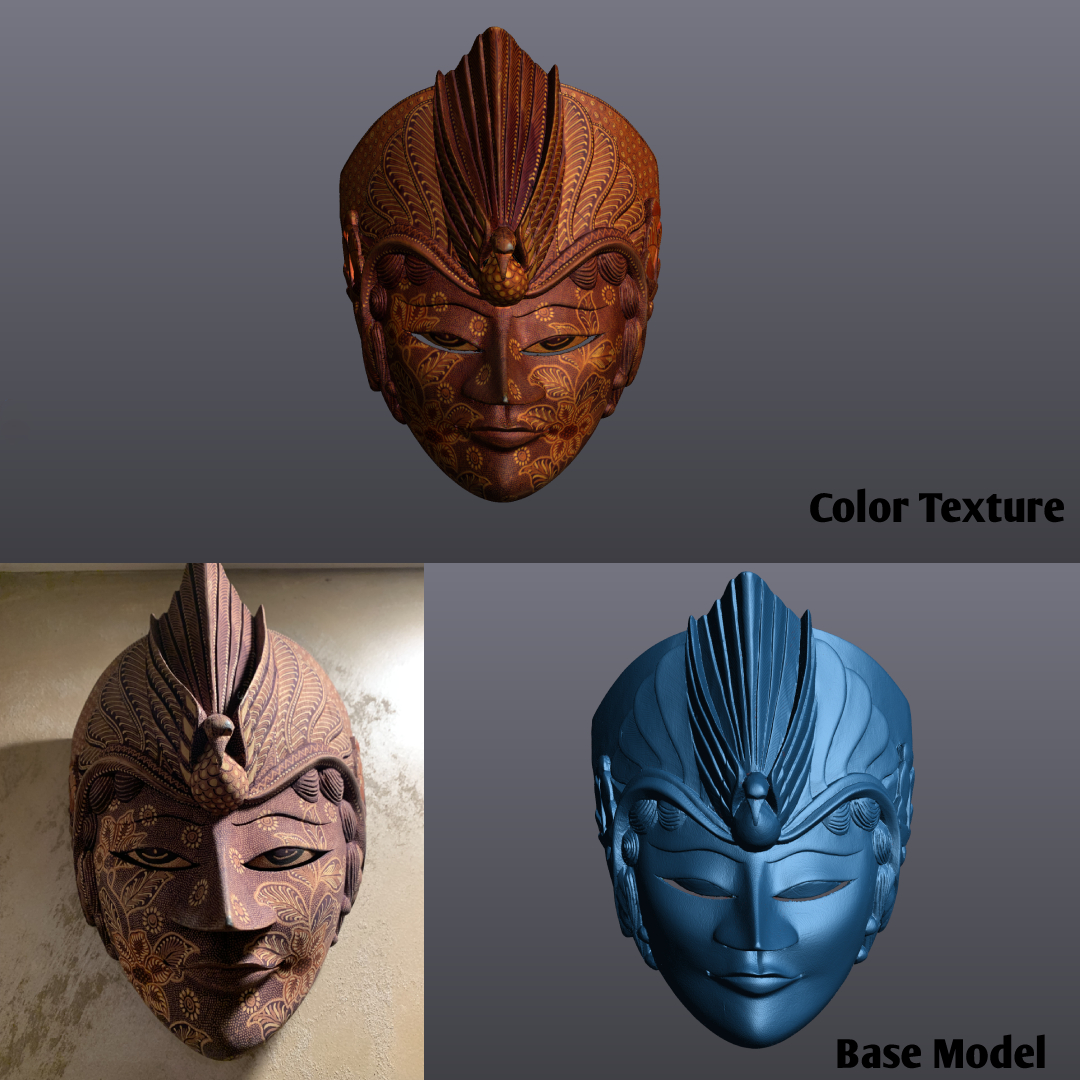

Cultural Heritage: Museums utilize detailed meshes and texture maps to preserve and study ancient artifacts digitally.

3D scan data with and without texture

Video Games: Game developers create immersive worlds using models enhanced with normal and displacement maps.

Construction and Architecture: Facilitates renovations and expansions by creating detailed models of existing structures.

Forensics and Law Enforcement: Captures crime scenes in detailed 3D models for investigations and legal proceedings.

Healthcare and Medical: Aids in customizing prosthetics, planning surgeries, and educational modeling.

Fashion and Apparel: Ensures better fits in clothing and footwear through precise body scanning.

Education and Research: Helps in creating replicas for study and aids various research projects.

Food Industry: Analyzes food shape and volume for quality control.

Art and Sculpture: Enables artists to capture and reproduce their works digitally for larger installations or archiving.

Spotlight on: Reverse Engineering

Reverse engineering is one of the most fascinating and critical applications of 3D scanning data. By capturing a physical object’s precise dimensions and translating them into digital models, engineers and designers can dissect complex assemblies, understand material compositions, and uncover manufacturing techniques of legacy parts. This process is essential not just for replicating parts but also for enhancing and optimizing existing designs. In sectors like automotive and aerospace, where legacy support and improvement are crucial, 3D scanning provides a bridge between old designs and new technologies, enabling companies to retrofit older equipment with modern, more efficient systems.

3D scanning might seem like just another trick up the modern tech sleeve, but it’s actually a superhero in the digital realm, rescuing projects in distress and giving new life to old designs. Whether you’re looking to capture the curves of a classic car or the intricate details of a cherished artifact, 3D scanning is your go-to technology hero.